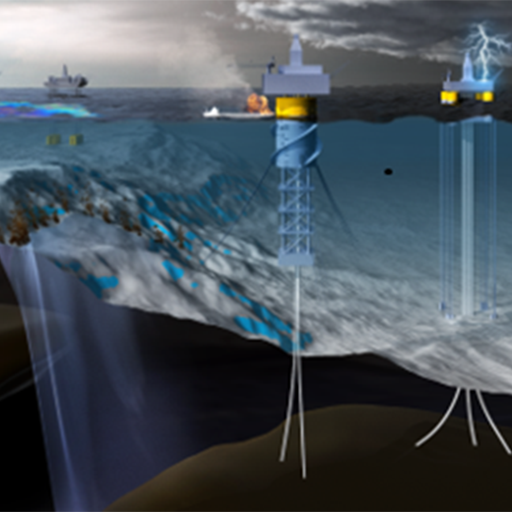

NETL’s Advanced Offshore Research Portfolio is a suite of projects that focuses on innovative solutions to solve the challenges associated with geohazard prediction, subsurface uncertainty reduction, and oil and gas infrastructure integrity and optimization for new and existing infrastructure systems.

These technologies and advances reduce the likelihood of, and prevent impacts from, damaging events associated with offshore oil and gas drilling and production, while improving the economic potential of these domestic resources.

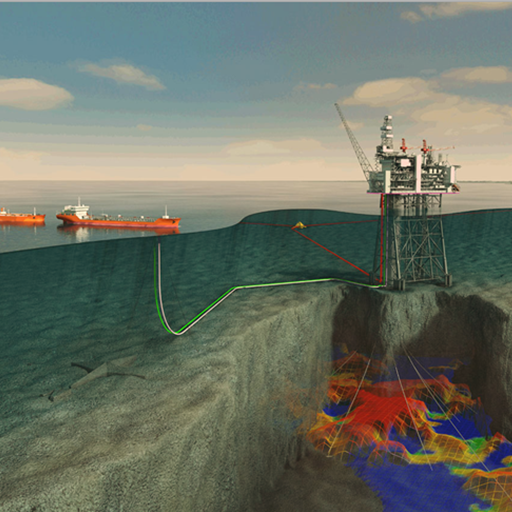

Infrastructure is key to all phases of offshore operations—spanning exploration and production through distribution. Offshore facilities and infrastructure in federal waters span the sea surface to the subsurface, including subsea installations and more than:

-

5,300 miles of pipelines

-

7,100 risers and platforms

-

120,000 wellbores

They are exposed to unique metocean conditions, as well as some of the deepest, hottest, and most chemically challenging geologic conditions on the planet.

Current research projects within the portfolio focus on spill prevention by:

Improving the ability to predict geologic hazards by identifying subsurface issues early, with greater accuracy and faster response time.

-

- Geohazard identification and mapping through improved mapping and modeling of deep subsurface and sub-salt sediments to determine overpressure zones

- Geohazard prediction using big data analytics, along with utilization of the Phase 1 Offshore Risk Modeling (ORM) platform of tools to support enhanced spill risk reduction

Preventing offshore incidents by managing and minimizing risks associated with drilling and production operations, aging infrastructure, and infrastructure reuse.

-

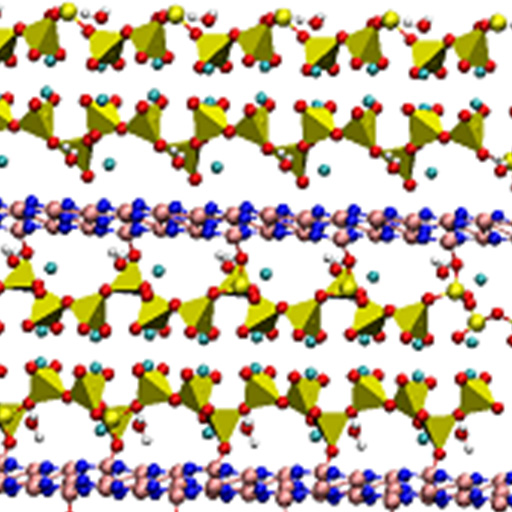

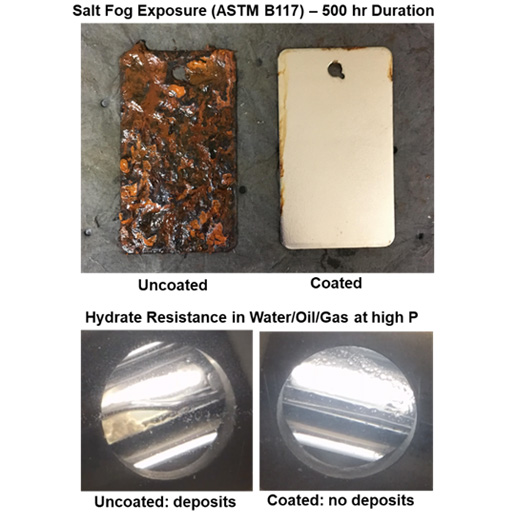

- Improving understanding of materials performance (metals and cement) under extreme conditions of temperature and pressure, with the presence of contaminants in wellbore fluids, and under varied oceanographic conditions

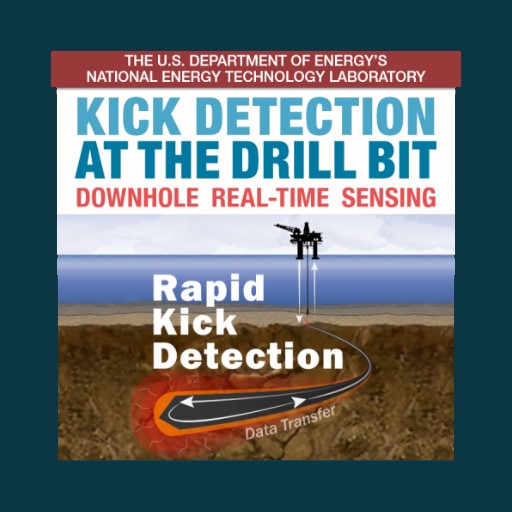

Minimizing drilling risks to prevent catastrophic offshore incidents and loss of life.

-

- Developing new models and technologies to further understand the Gulf of Mexico, Arctic, Atlantic, and Pacific metocean risks

Enabling offshore Enhanced Oil Recovery (EOR) advanced subsea systems technologies to improve efficiency and capabilities for EOR in offshore wells.

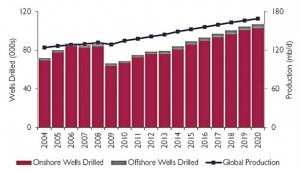

Offshore oil and gas production is key to meeting global and domestic demand. Globally, offshore drilling accounts for less than 5 percent of the world’s wells, yet it accounts for nearly 30 percent of total global oil production. Further, as new offshore discoveries come online, the volume of domestic oil and gas production from the Gulf of Mexico is forecast to increase significantly in the near term.*

In response to this increase in production, NETL researchers are developing technologies and advanced analytics to equip oil-and-gas decision makers with the tools and data they need to reduce costs and reduce risk.

NETL is using Advanced Spatio-Temporal Analytics, Big Data Computing, and Machine Learning to predict, prepare for, and prevent offshore costs and risk.

NETL is Using Advanced Spatio-Temporal Analytics, Big Data Computing, and Machine Learning to Predict, Prepare, and Prevent Offshore Costs and Risk

Preventing

Spills

Even relatively small oil spills can cause major harm, depending on the location, season, environmental sensitivity, and type of oil. To help improve spill prevention efforts, the oil and gas industry needs intelligent, data-driven, science-based solutions.

NETL’s Advanced Offshore Research Portfolio specifically conducts research that R&D professionals in industry need to predict, prepare for, and prevent offshore spills, as well as to address challenges regarding geologic/subsurface uncertainty, drilling and completion operations, surface systems and facilities, and subsea systems’ reliability and automation.

Where many R&D projects are focused solely on spill response, NETL’s Advanced Offshore Research Portfolio projects seek to provide spill-prevention solutions, seeking to eliminate environmental and economic issues before they occur.

Reducing

Cost & Risk

Exploratory drilling is one of the riskiest, costliest, and most prospective types of oil and gas operations. Deepwater production, or production in water of depths greater than 125 meters, has increased 25 percent from nearly 7 million barrels per day only a decade ago.

NETL’s Advanced Offshore Research Portfolio develops technologies and public information that can be used to assess and mitigate risks and costs associated with offshore oil spills prior to, during drilling and production operations, and for decades following when wells are plugged and abandoned.

Drilling at these extreme temperatures and pressures requires advanced materials and knowledge of how these materials perform under extreme conditions.

Keeping People &

the Environment Safe

Protecting people and the environment from the threat of offshore oil spills is fundamental to our research. Researchers are developing advanced Offshore Risk Modeling tools and models to assess trends associated with simulated oil spills and the potential social, economic, and environmental impacts they could pose.

NETL’s Advanced Offshore Research Portfolio develops and demonstrates innovative technologies to provide industry and regulators fresh insights that enhance and establish new practices, policies, and regulations to improve safety, mitigate geohazards, minimize equipment failure, reduce costs, and prevent future spills—keeping people and the environment safe.

Understanding potential impacts helps oil-and-gas decision makers arrive at safe, intelligent, and informed decisions associated with oil extraction and production.