Overview

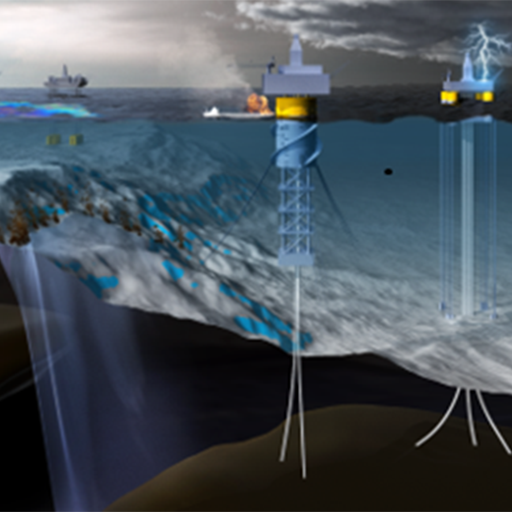

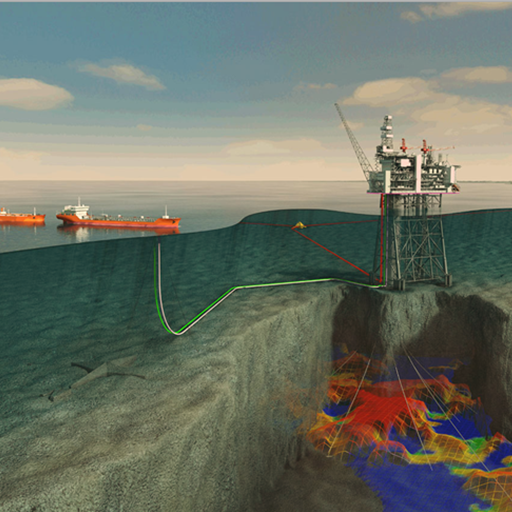

This research will be used to directly influence and improve safety practices in the oil and gas industry. NETL will better define the transition of a cement slurry from a liquid to a gel, where it develops sufficient gel strength to prevent the influx of external fluids into the cement column, to minimize drilling risks from gas and fluid migration. Controlling the influx of external fluids into the cement column ensures wellbore integrity and prevents blowouts.

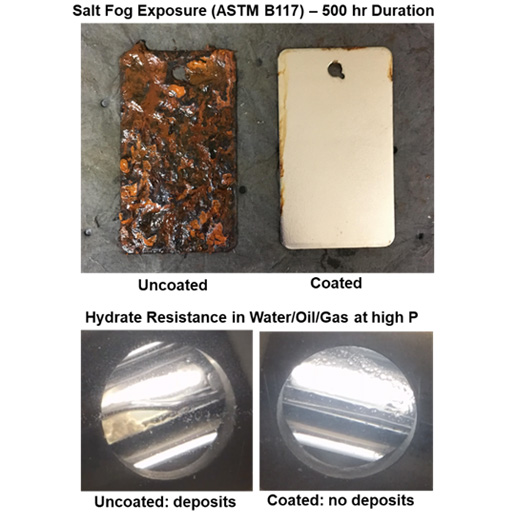

In the wellbore, cement is the barrier between the steel well casing at the center of the wellbore and the formation. The cement is designed to prevent fluid from the formation from penetrating the cement and causing fluid pathways through the cement sheath. Any gas or fluid migration in the cement sheath can lead to loss of zonal isolation and potentially the presence of gas or liquids at surface. This can result in loss of production, interzonal communication or hydrocarbons at surface.

The American Petroleum Institute (API) develops standard recommended practices to improve safe drilling practices. The oil and gas industry testing practices measure multiple cement slurry properties prior to placement to ensure its integrity. NETL has partnered with the API to review and improve recommended practices for testing the cement gel strength based on the research conducted at the NETL.

Industry measures the static gel strength (SGS) as a method to determine the time it takes for the cement slurry to gel once it has been placed in the well. The test is designed to measure the gel strength development of the slurry and determine the point at which the system can prevent fluids from penetrating the cement column. This measurement is critical for many oil and gas well construction designs and operations. However, results obtained from different SGS devices are not comparable due to different designs and operating practices for measuring SGS. It is the intent of this research to work with industry to improve the correlation between the different measurements.

Approach

This research project is being conducted in collaboration with the American Petroleum Institute (API), industry experts, and manufacturers. This multi-phase, three-year project is combining experimental data collected by NETL researchers, analysis of the API’s laboratory test results, and fundamental physics.

In the first phase of the project, NETL researchers have developed an understanding of the science behind the measurements that industry designed. NETL has established a path forward with the API and the manufacturers involved in the study and begun testing in the laboratory. NETL works directly with the API and the manufacturers in establishing the essential revisions to properly measure the static gel strength. NETL researchers have also been working with the SGS instrument manufacturers to establish a standard testing material to verify static gel strength measurements and confirm any equipment changes implemented have been done so correctly.

Once the measurements have been verified with a standard material, NETL will begin to test the SGS instruments to experimentally determine the various influencing parameters and how they impact the results so that the changes can be implemented into the recommended practices. NETL will work with industry to determine the various tests that need to be run, the relevant parameters, and the range of values of the parameters. The results will be combined with theoretical knowledge regarding the instruments, as well as cement slurry behavioral properties. NETL will work with the API to establish standard protocols for inclusion in API recommended practices.

Expected Outcome

NETL’s research has shown that the SGS measurements vary due to the different approaches to determining the stress. Once corrections have been made which consider the specifics of the machine designs, the SGS instruments currently on the market can be used to measure cement slurries with better correlation among different machines.

Research Products

Pulsating Poiseuille Flow of a Cement Slurry

Tao, C., Rosenbaum, E., Kutchko, B., and Massoudi, M., “Pulsating Poiseuille Flow of a Cement Slurry,” International Journal of Non-Linear Mechanics, Vol. 133 (2021), 103717, ISSN: 0020-7462, https://doi.org/10.1016/j.ijnonlinmec.2021.103717.

A Brief Review of Gas Migration in Oilwell Cement Slurries

Tao, C., Rosenbaum, E. , Kutchko, B.G., Massoudi, M., A Brief Review of Gas Migration in Oilwell Cement Slurries. Energies 2021, 14, 2369. https://doi.org/10.3390/en14092369

The Importance of Vane Configuration on Yield Stress Measurements of Cement Slurry

Tao, C.; Rosenbaum, E.; Kutchko, B.; Massoudi, M. The Importance of Vane Configuration on Yield Stress Measurements of Cement Slurry; DOE/NETL- 020/2116; NETL Technical Report Series; U.S. Department of Energy, National Energy Technology Laboratory: Morgantown, WV, 2020; p 24. DOI:

10.18141/1614691. https://netl.doe.gov/sites/default/files/netl-file/ImportanceofVaneConfigurationonYieldStressMeasurementsofCementSlurry_04142020.pdf

Building Regional Baselines and a Suite of Spatial Tools to Better Prepare for Oil Spills

Romeo, L., Dyer, A., Nelson, J., Bauer, J., Rose, K., Dao, A., Wingo, P., and Sabbatino, M., “Building Regional Baselines and a Suite of Spatial Tools to Better Prepare for Oil Spills,” American Geophysical Union (AGU) Ocean Sciences, February 2020

https://agu.confex.com/agu/osm20/meetingapp.cgi/Home/0

Building an Analytical Framework to Measure Offshore Infrastructure Integrity, Identify Risk, and Strategize Future Use for Oil and Gas

Dyer, A., Rose, K., Bauer, J., Romeo, L., Barkhurst, A., Wingo, P., Sabbatino, M., Nelson, J., and Wenzlick, M., “Building an Analytical Framework to Measure Offshore Infrastructure Integrity, Identify Risk, and Strategize Future Use for Oil and Gas,” American Geophysical Union (AGU) Ocean Sciences, February 2020

https://www.agu.org/Ocean-Sciences-Meeting

A Review of Rheological Modeling of Cement Slurry in Oil Well Applications

Tao, C., Kutchko, B., Rosenbaum, E., and Massoudi, M., “A Review of Rheological Modeling of Cement Slurry in Oil Well Applications,” Energies, 13 (2020), 570, DOI:10.3390/en13030570, https://www.mdpi.com/1996-1073/13/3/570/pdf.

Flow of Cement Slurry in a Vertical Pipe

Accepted for presentation at the 2019 Joint Mathematics Meetings (JMM), American Mathematical Society (AMS), Mathematical Association of America (MAA), Baltimore, MD, Jan 16–19, 2019.

Tao, C.; Rosenbaum, E.; Kutchko, B.; Massoudi, M.

http://jointmathematicsmeetings.org/meetings/national/jmm2019/2217_intro

Effects of Shear-Rate Dependent Viscosity on the Flow of a Cement Slurry

Poster presented at the Dynamics Days 2019, International Conference on Nonlinear Dynamics, Northwestern University, Evanston, IL, Jan 4–6, 2019.

Tao, C.; Rosenbaum, E.; Kutchko, B.; Massoudi, M.

Static Gel Strength Working Group Update to the API Sub-Committee on Oil Well Cements (SC 10)

American Petroleum Institute (API) Winter Standards Meeting, San Antonio, TX, Jan 21–24, 2019.

Rosenbaum, E.; Benge, G.

NETL Research Update

Presented at the API 2019 Exploration and Production Standards Conference, in New Orleans, Louisiana, June 24–27, 2019.

Rosenbaum, E. NETL Research Update.

Steady Flow of a Cement Slurry

Energies 2019, 12(13), 2604.

Tao, Chengcheng & G Kutchko, Barbara & Rosenbaum, Eilis & Wu, Wei-Tao & Massoudi, Mehrdad.

https://www.researchgate.net/publication/334277526_Steady_Flow_of_a_Cement_Slurry/citation/download

Explore research products that are related to this project.

Contacts

Eilis Rosenbaum

Principal Investigator

Kelly Rose

Offshore Portfolio Lead

Roy Long

Offshore Portfolio Technical Manager

Effective Resource Development

Alexandra Hakala

Senior Fellow (Detail)

Geological & Environmental Systems

Philip Reppert

Associate Director

Geological & Environmental Systems