NETL Expert to Speak at Gulf Offshore Energy Safety Informational Webinar

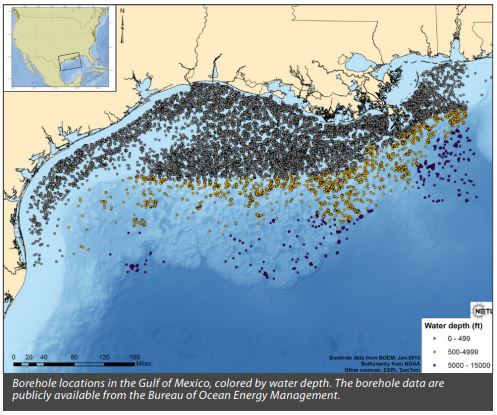

NETL geo-data scientist Jennifer Bauer will discuss the Lab’s research activities focused on legacy oil and gas infrastructure — retired pipelines, platforms and other structures that remain in place after abandonment or end of use — at the Gulf Offshore Energy Safety Informational Webinar to be held from 11 a.m. to noon ET Thursday, Nov. 3, 2022.

NETL-Funded Project Among Finalists In 2022 IChemE Global Awards

The University of North Dakota’s Energy & Environmental Research Center’s (EERC) Produced Water Management Through Geologic Homogenization, Conditioning and Reuse (GHCR) project — funded by NETL and developed in partnership with the North Dakota Industrial Commission Oil and Gas Research Program and Nuverra Environmental Solutions — is a finalist in the Oil and Gas category of the 2022 Institution of Chemical Engineers (IChemE) Global Awards.

NETL Researcher to Share Expertise on Advancing Well Integrity

Barbara Kutchko, a senior researcher at NETL who develops advanced cement systems to reduce the environmental footprint of drilling operations, will serve as a key organizer and presenter at Cementing in an Unconventional World, a workshop presented by the Society of Petroleum Engineers (SPE) Sept. 27-29, 2022, in Galveston, Texas.

NETL’s AI-informed Offshore Infrastructure Integrity Model Selected as TechConnect National Innovation Awardee

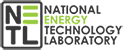

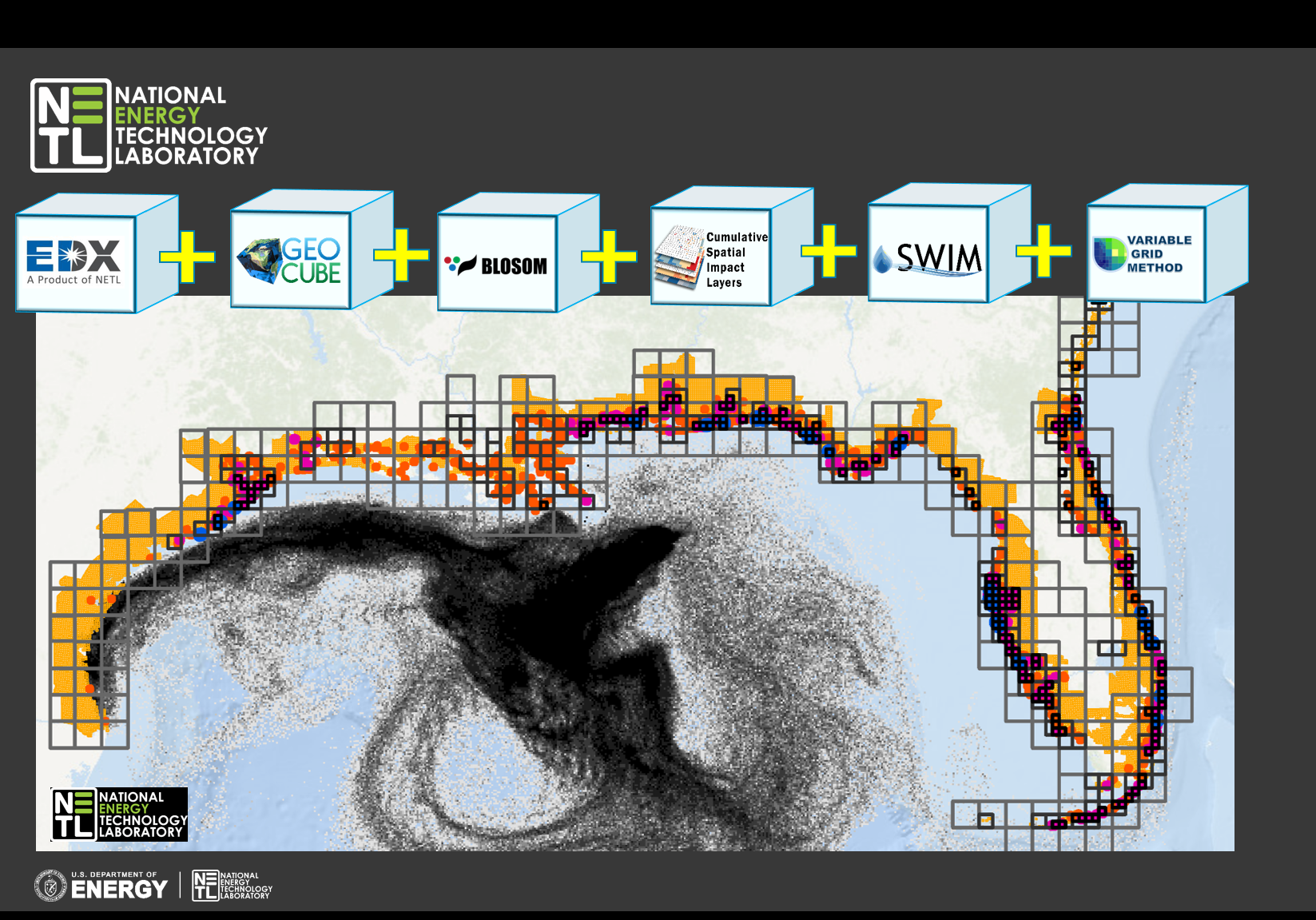

NETL’s Advanced Infrastructure Integrity Model (AIIM) is a science-based, artificial intelligence, big data, and big data computing informed approach to assessing offshore energy infrastructure integrity for safe future use and repurposing. AIIM is the latest advancement in the 2019 R&D 100 award-winning Offshore Risk Modeling suite, and was recognized as a top-ranked innovation and selected as a TechConnect National Innovation Awardee. Additional information on NETL’s participation at TechConnect was featured as an NETL story here: NETL Connects with Industry at National Innovation Symposium | netl.doe.gov.

NETL’S Ocean Current Forecasting Tool Used in Great Pacific Garbage Patch Cleanup Effort

NETL tool is being used to monitor the Great Pacific Garbage Patch for cleanup activities. A digital tool developed by NETL that helps examine ocean currents and wind patterns to predict where oil and other particles in the ocean are likely to travel in the event of an oil spill is being used for a range of non-energy related uses: like keeping track of the Great Pacific Garbage Patch for cleanup activities. NETL’s Kelly Rose, Ph.D., explained that Climatological and Instantaneous Isolation and Attraction Model (CIIAM) was developed within NETL’s Advanced Offshore Research portfolio (AOR) as one of several projects initiated because of lessons learned following the 2010 Deepwater Horizon oil spill in the Gulf of Mexico. That event highlighted the need for improved models, data and tools to prevent future events, and improve response preparedness.

NETL Drilling, Subsurface Research Featured in New Book

Scientists from NETL were invited by book editors from NASA’s Jet Propulsion Laboratory (JPL) and Honeybee Robotics to include a chapter focusing on a portion of its research program related to Environmental Drilling as part of the recently released book “Advances in Terrestrial Drilling: Ground, Ice, and Underwater.” The book details the latest drilling and excavation principles and processes for terrestrial environments. Many years of research by the U.S. Department of Energy (DOE) in this area is detailed, including NETL’s offshore research, as the focus of the book’s seventh chapter, “Environmental Drilling / Sampling and Offshore Modeling Systems.”

With carbon capture funding, Trump and Biden have common ground on energy jobs

U.S. Energy Secretary Dan Brouillette was in the Pittsburgh region Wednesday to announce about $80 million in federal funding to demonstrate that coal, natural gas and other materials can be cleanly burned for electricity with technology that can capture carbon.

NETL’s Offshore Risk Modeling Simulation Tool Garners International Use

A digital tool developed by NETL researchers in collaboration with researchers from the University of Miami to make offshore oil production safer is being used around the world to inform a range of critical hydrocarbon exploration activities.

Putting Big Data To Work For Offshore Insights

A modeling suite addresses key knowledge gaps to improve the prediction and evaluation of offshore systems for improved spill prevention and more.

Researchers Working to Connect the Dots Between Bubbles and Viscosity in Foamed Cement

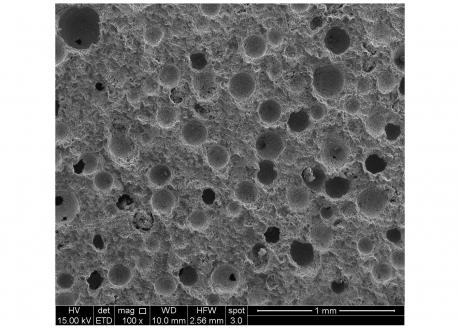

A team of researchers from NETL and Carnegie Mellon University (CMU) recently developed equations to more simply determine how the viscosity of foamed cement is affected by the addition of bubbles into the slurry. Understanding the connection between an increase of bubbles concentration and the ensuing changes in viscosity is crucial for predicting how well the foamed cement will perform in wellbores, which will enable safer oil and gas production. The work was recently featured in a special issue of Fluids, an international journal.

NETL Honored with Three R&D 100 Awards

R&D World magazine announced that three groundbreaking NETL technologies will receive prestigious R&D 100 awards for being among the 100 most technologically significant products introduced into the marketplace in the last year.

2019 ECN Oil & Gas Machine Learning Conference, Houston

NETL’s SIMPA data-driven subsurface leak prediction. Vol. 24 N° 4, Oil Information Technology Journal.

NETL-Developed Digital Suite Prevents and Predicts Oil Spills

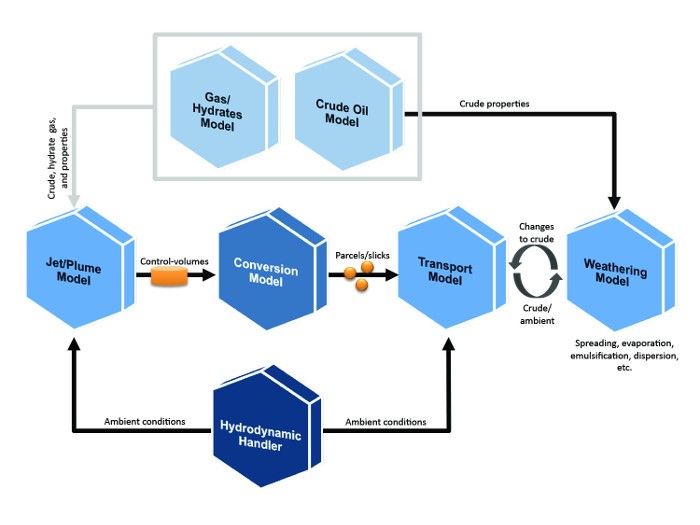

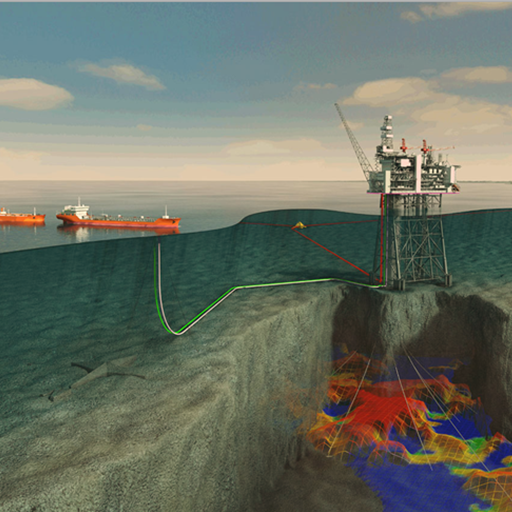

To address the unique challenges associated with offshore hydrocarbon exploration, researchers from NETL’s Geo-Analysis & Monitoring Team created the Offshore Risk Modeling (ORM) suite to evaluate and reduce the risk of oil spill events. Consisting of eight digital modeling and visualization tools, the ORM suite represents more than six years of development, innovation and validation, resulting in a robust suite of advanced tools that are easily accessible for use by researchers and operators. The suite provides a comprehensive framework for future predictions, analyses and visualizations surrounding oil spill scenarios to better inform offshore drilling efforts, which works to make extracting critical resources safer while ensuring environmental protection.

Innovative Earth-Energy Data Computing Tools Provide Critical Information for Decision-Makers

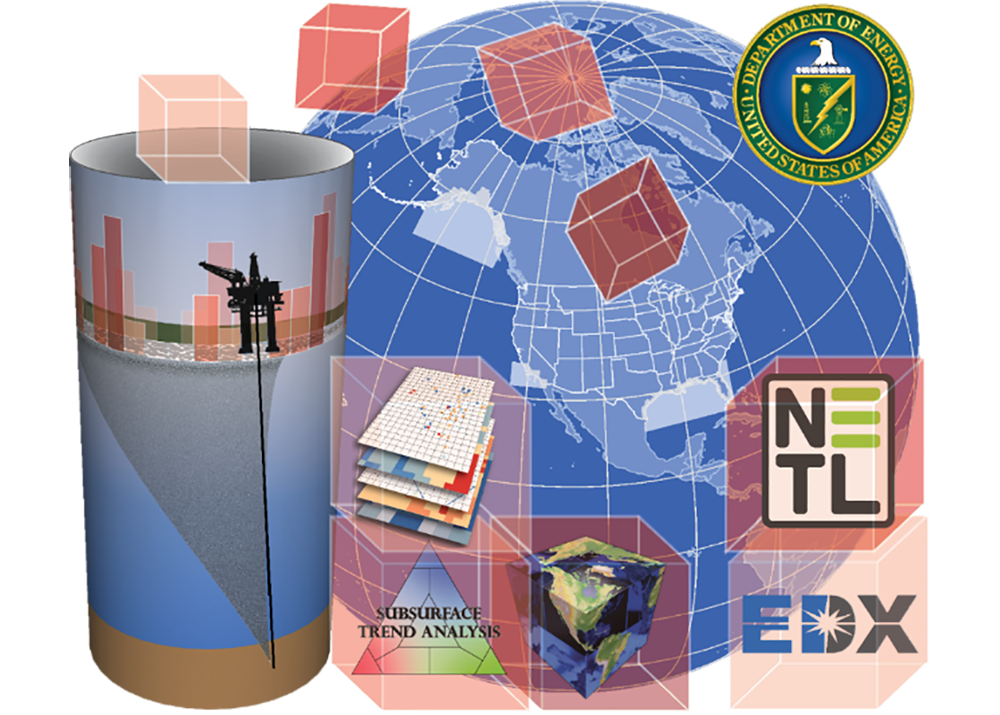

As stakeholders in energy activities seek to improve resource recovery or storage, minimize risks and reduce adverse impacts, they increasingly rely on powerful computing tools that provide critical science-based predictions.

NETL’s geo-data science experts have developed seven novel big and small data computing solutions now available for licensing that address comprehensive Earth, energy, environmental and engineering needs. These innovative tools offer accurate science-based data, analysis and prediction for Earth-energy applications – including big data and machine learning capabilities – to industry, governments, researchers and other stakeholders requiring research-driven data for energy operations.

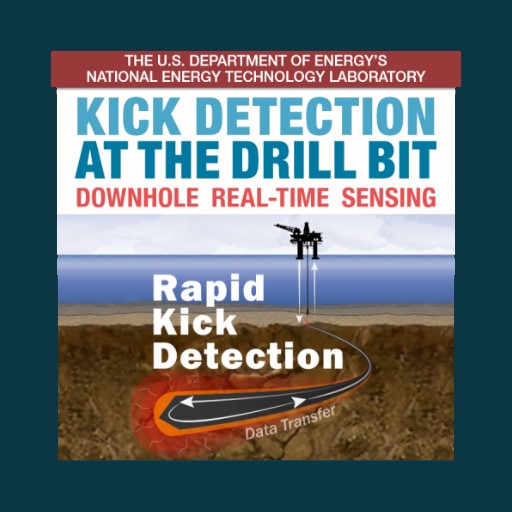

NETL’s Early Kick Detection

NationalEnergyAwarenessMonth continues. Here’s an #NETL success that is contributing toward our nation’s Energy Independence and Environmental Protection: NETL’s Early Kick Detection. This innovation helps prevent well blowouts by detecting kicks at the drill bit.

Learn more. https://www.netl.doe.gov/sites/default/files/rdfactsheet/R-D210_0.pdf

NETL Offshore Research Innovation Featured in Prestigious Nature Publication, Scientific Reports

NETL has been at the forefront of research to make offshore energy production safer and more efficient ever since the Lab helped assess the Macondo Oil Spill in 2010. Now, a component of that expertise is front and center in a new article appearing March 26 in the prestigious journal Scientific Reports, released by Nature Publishing Group.

NETL’s Well-bore Integrity Team were announced as a finalist for the 2017 World Oil Awards in the Best Health, Safety, Environment/ Sustainable Development – Offshore Award category

The 2017 World Oil Award finalists have been announced, and NETL’s Well-Bore Integrity Team has been named a finalist! Led by Dr. Barbara Kutchko, seen here, the team was nominated in the Best Heath, Safety, Environment/Sustainable Development—Offshore Award category for their work advancing foamed cementing technology—an accomplishment that is leading to safer, more sustainable offshore drilling. Congratulations to the team!

Instantly ‘See’ Drilling Kicks With MWD/LWD Data

We live in a world increasingly defined and characterized by the acquisition, processing and use of data. Most of these data streams are designed to address a specific question or need, like heart rate on a fitness tracker, the temperature history recorded on a home’s thermostat and more. However, data are tricky in that often the same data can be reused to address multiple questions or needs. But first, one has to ask the right questions.

Tech Talk — Real-time ‘kick’ monitoring can help prevent blowouts

Gushers are signs of failures — not successes.

We vicariously enjoy movie scenes when a well gushes oil and showers characters such as those portrayed by James Dean in “Giant” and Daniel Day-Lewis in “There will be Blood.” Under authentic settings, gushers often were viewed from a distance (Figure 1). However, to oilmen, a gusher is a dramatic sign of failure with an accompanying loss of valuable oil, expensive equipment, and — in many instances — a loss of roustabouts.

Many formations contain gases, oil, and water under high pressure and these start flowing, or blow out, when or after a well has been drilled through the formation. Blowouts of water are artesian wells and blowouts of oil are gushers.

NETL’s Kick Technology named 2017 Shale Gas Innovation Contest’s Innovation R&D Winner

On May 9th in Pittsburgh during the 6th Annual Shale Gas Innovation Contest the following three companies each walked away with a winner’s check for $20,000.

In addition to the three winners, a fourth technology submitted by the Department of Energy’s National Energy Technology Laboratory (NETL) by Kelly Rose, Technology Geology & Geospatial Researcher, was highly praised by the contest judges and attendees, and was named the contest’s Innovative R&D Winner.

NETL takes new kick-detection idea to contest

Drilling for oil and gas may be safer and less expensive in the future, thanks to researchers at the U.S. Department of Energy.

Scientists working in the National Energy Technology Laboratory have developed a way to predict well kicks and alert operators before they happen using the same technology already guiding the bit underground.

The researchers’ work is one of 10 finalists in the sixth annual Shale Gas Innovation Contest sponsored by the Shale Gas Innovation and Commercialization Center. The winner will be determined May 9.

Research examines differences between foamed cement slurries in laboratory, field

The National Energy Technology Laboratory (NETL) and the American Petroleum Institute’s (API) Cement Subcommittee 10 have been working closely together the past few years to examine the differences between foamed slurries generated with laboratory equipment and field foamed cementing equipment.

Research advances foamed cement applications

The National Energy Technology Laboratory (NETL) and the American Petroleum Institute’s (API) Cement Subcommittee 10C are working together to close the knowledge gap regarding the stability and properties of foamed cement as it is placed in the well. Researchers at NETL are comparing foamed cement samples that were mixed and tested at atmospheric conditions in a laboratory against those generated in the field and collected prior to being pumped into a wellbore.

Kick detection system provides early warnings for safer drilling

The perception of oil and gas well control has evolved over the last century. In the late 1800s and early 1900s, blowouts were held in high esteem, with “gushers” romanticized as a symbol of prosperity. Over time, however, these gushers became associated with the destruction of materials, human and environmental impacts, and a loss of marketable resources, leading to development of well control technologies.

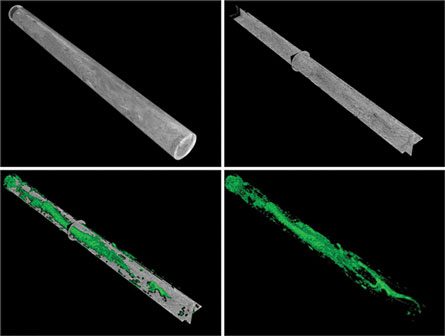

Early Kick Detection: Testing New Concepts

After the 2010 subsea blowout of the Macondo well that resulted in 11 deaths and the worst oil spill in US history, early kick detection technology found itself at the top of the wish list for regulators and offshore companies seeking to avoid similar accidents. The National Commission on the BP Deepwater Horizon Oil Spill concluded that the crew lacked both training and the technology to recognize the critical signs that a kick was occurring.

NETL Expert to Speak at Gulf Offshore Energy Safety Informational Webinar

NETL geo-data scientist Jennifer Bauer will discuss the Lab’s research activities focused on legacy oil and gas infrastructure — retired pipelines, platforms and other structures that remain in place after abandonment or end of use — at the Gulf Offshore Energy Safety Informational Webinar to be held from 11 a.m. to noon ET Thursday, Nov. 3, 2022.

NETL-Funded Project Among Finalists In 2022 IChemE Global Awards

The University of North Dakota’s Energy & Environmental Research Center’s (EERC) Produced Water Management Through Geologic Homogenization, Conditioning and Reuse (GHCR) project — funded by NETL and developed in partnership with the North Dakota Industrial Commission Oil and Gas Research Program and Nuverra Environmental Solutions — is a finalist in the Oil and Gas category of the 2022 Institution of Chemical Engineers (IChemE) Global Awards.

NETL Researcher to Share Expertise on Advancing Well Integrity

Barbara Kutchko, a senior researcher at NETL who develops advanced cement systems to reduce the environmental footprint of drilling operations, will serve as a key organizer and presenter at Cementing in an Unconventional World, a workshop presented by the Society of Petroleum Engineers (SPE) Sept. 27-29, 2022, in Galveston, Texas.

NETL’s AI-informed Offshore Infrastructure Integrity Model Selected as TechConnect National Innovation Awardee

NETL’s Advanced Infrastructure Integrity Model (AIIM) is a science-based, artificial intelligence, big data, and big data computing informed approach to assessing offshore energy infrastructure integrity for safe future use and repurposing. AIIM is the latest advancement in the 2019 R&D 100 award-winning Offshore Risk Modeling suite, and was recognized as a top-ranked innovation and selected as a TechConnect National Innovation Awardee. Additional information on NETL’s participation at TechConnect was featured as an NETL story here: NETL Connects with Industry at National Innovation Symposium | netl.doe.gov.

NETL’S Ocean Current Forecasting Tool Used in Great Pacific Garbage Patch Cleanup Effort

NETL tool is being used to monitor the Great Pacific Garbage Patch for cleanup activities. A digital tool developed by NETL that helps examine ocean currents and wind patterns to predict where oil and other particles in the ocean are likely to travel in the event of an oil spill is being used for a range of non-energy related uses: like keeping track of the Great Pacific Garbage Patch for cleanup activities. NETL’s Kelly Rose, Ph.D., explained that Climatological and Instantaneous Isolation and Attraction Model (CIIAM) was developed within NETL’s Advanced Offshore Research portfolio (AOR) as one of several projects initiated because of lessons learned following the 2010 Deepwater Horizon oil spill in the Gulf of Mexico. That event highlighted the need for improved models, data and tools to prevent future events, and improve response preparedness.

NETL Drilling, Subsurface Research Featured in New Book

Scientists from NETL were invited by book editors from NASA’s Jet Propulsion Laboratory (JPL) and Honeybee Robotics to include a chapter focusing on a portion of its research program related to Environmental Drilling as part of the recently released book “Advances in Terrestrial Drilling: Ground, Ice, and Underwater.” The book details the latest drilling and excavation principles and processes for terrestrial environments. Many years of research by the U.S. Department of Energy (DOE) in this area is detailed, including NETL’s offshore research, as the focus of the book’s seventh chapter, “Environmental Drilling / Sampling and Offshore Modeling Systems.”

With carbon capture funding, Trump and Biden have common ground on energy jobs

U.S. Energy Secretary Dan Brouillette was in the Pittsburgh region Wednesday to announce about $80 million in federal funding to demonstrate that coal, natural gas and other materials can be cleanly burned for electricity with technology that can capture carbon.

NETL’s Offshore Risk Modeling Simulation Tool Garners International Use

A digital tool developed by NETL researchers in collaboration with researchers from the University of Miami to make offshore oil production safer is being used around the world to inform a range of critical hydrocarbon exploration activities.

Putting Big Data To Work For Offshore Insights

A modeling suite addresses key knowledge gaps to improve the prediction and evaluation of offshore systems for improved spill prevention and more.

Researchers Working to Connect the Dots Between Bubbles and Viscosity in Foamed Cement

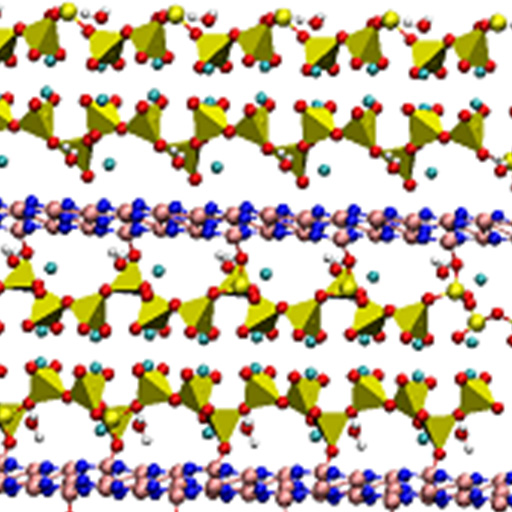

A team of researchers from NETL and Carnegie Mellon University (CMU) recently developed equations to more simply determine how the viscosity of foamed cement is affected by the addition of bubbles into the slurry. Understanding the connection between an increase of bubbles concentration and the ensuing changes in viscosity is crucial for predicting how well the foamed cement will perform in wellbores, which will enable safer oil and gas production. The work was recently featured in a special issue of Fluids, an international journal.

NETL Honored with Three R&D 100 Awards

R&D World magazine announced that three groundbreaking NETL technologies will receive prestigious R&D 100 awards for being among the 100 most technologically significant products introduced into the marketplace in the last year.

2019 ECN Oil & Gas Machine Learning Conference, Houston

NETL’s SIMPA data-driven subsurface leak prediction. Vol. 24 N° 4, Oil Information Technology Journal.

NETL-Developed Digital Suite Prevents and Predicts Oil Spills

To address the unique challenges associated with offshore hydrocarbon exploration, researchers from NETL’s Geo-Analysis & Monitoring Team created the Offshore Risk Modeling (ORM) suite to evaluate and reduce the risk of oil spill events. Consisting of eight digital modeling and visualization tools, the ORM suite represents more than six years of development, innovation and validation, resulting in a robust suite of advanced tools that are easily accessible for use by researchers and operators. The suite provides a comprehensive framework for future predictions, analyses and visualizations surrounding oil spill scenarios to better inform offshore drilling efforts, which works to make extracting critical resources safer while ensuring environmental protection.

Innovative Earth-Energy Data Computing Tools Provide Critical Information for Decision-Makers

As stakeholders in energy activities seek to improve resource recovery or storage, minimize risks and reduce adverse impacts, they increasingly rely on powerful computing tools that provide critical science-based predictions.

NETL’s geo-data science experts have developed seven novel big and small data computing solutions now available for licensing that address comprehensive Earth, energy, environmental and engineering needs. These innovative tools offer accurate science-based data, analysis and prediction for Earth-energy applications – including big data and machine learning capabilities – to industry, governments, researchers and other stakeholders requiring research-driven data for energy operations.

NETL’s Early Kick Detection

NationalEnergyAwarenessMonth continues. Here’s an #NETL success that is contributing toward our nation’s Energy Independence and Environmental Protection: NETL’s Early Kick Detection. This innovation helps prevent well blowouts by detecting kicks at the drill bit.

Learn more. https://www.netl.doe.gov/sites/default/files/rdfactsheet/R-D210_0.pdf

NETL Offshore Research Innovation Featured in Prestigious Nature Publication, Scientific Reports

NETL has been at the forefront of research to make offshore energy production safer and more efficient ever since the Lab helped assess the Macondo Oil Spill in 2010. Now, a component of that expertise is front and center in a new article appearing March 26 in the prestigious journal Scientific Reports, released by Nature Publishing Group.

NETL’s Well-bore Integrity Team were announced as a finalist for the 2017 World Oil Awards in the Best Health, Safety, Environment/ Sustainable Development – Offshore Award category

The 2017 World Oil Award finalists have been announced, and NETL’s Well-Bore Integrity Team has been named a finalist! Led by Dr. Barbara Kutchko, seen here, the team was nominated in the Best Heath, Safety, Environment/Sustainable Development—Offshore Award category for their work advancing foamed cementing technology—an accomplishment that is leading to safer, more sustainable offshore drilling. Congratulations to the team!

Instantly ‘See’ Drilling Kicks With MWD/LWD Data

We live in a world increasingly defined and characterized by the acquisition, processing and use of data. Most of these data streams are designed to address a specific question or need, like heart rate on a fitness tracker, the temperature history recorded on a home’s thermostat and more. However, data are tricky in that often the same data can be reused to address multiple questions or needs. But first, one has to ask the right questions.

Tech Talk — Real-time ‘kick’ monitoring can help prevent blowouts

Gushers are signs of failures — not successes.

We vicariously enjoy movie scenes when a well gushes oil and showers characters such as those portrayed by James Dean in “Giant” and Daniel Day-Lewis in “There will be Blood.” Under authentic settings, gushers often were viewed from a distance (Figure 1). However, to oilmen, a gusher is a dramatic sign of failure with an accompanying loss of valuable oil, expensive equipment, and — in many instances — a loss of roustabouts.

Many formations contain gases, oil, and water under high pressure and these start flowing, or blow out, when or after a well has been drilled through the formation. Blowouts of water are artesian wells and blowouts of oil are gushers.

NETL’s Kick Technology named 2017 Shale Gas Innovation Contest’s Innovation R&D Winner

On May 9th in Pittsburgh during the 6th Annual Shale Gas Innovation Contest the following three companies each walked away with a winner’s check for $20,000.

In addition to the three winners, a fourth technology submitted by the Department of Energy’s National Energy Technology Laboratory (NETL) by Kelly Rose, Technology Geology & Geospatial Researcher, was highly praised by the contest judges and attendees, and was named the contest’s Innovative R&D Winner.

NETL takes new kick-detection idea to contest

Drilling for oil and gas may be safer and less expensive in the future, thanks to researchers at the U.S. Department of Energy.

Scientists working in the National Energy Technology Laboratory have developed a way to predict well kicks and alert operators before they happen using the same technology already guiding the bit underground.

The researchers’ work is one of 10 finalists in the sixth annual Shale Gas Innovation Contest sponsored by the Shale Gas Innovation and Commercialization Center. The winner will be determined May 9.

Research examines differences between foamed cement slurries in laboratory, field

The National Energy Technology Laboratory (NETL) and the American Petroleum Institute’s (API) Cement Subcommittee 10 have been working closely together the past few years to examine the differences between foamed slurries generated with laboratory equipment and field foamed cementing equipment.

Research advances foamed cement applications

The National Energy Technology Laboratory (NETL) and the American Petroleum Institute’s (API) Cement Subcommittee 10C are working together to close the knowledge gap regarding the stability and properties of foamed cement as it is placed in the well. Researchers at NETL are comparing foamed cement samples that were mixed and tested at atmospheric conditions in a laboratory against those generated in the field and collected prior to being pumped into a wellbore.

Kick detection system provides early warnings for safer drilling

The perception of oil and gas well control has evolved over the last century. In the late 1800s and early 1900s, blowouts were held in high esteem, with “gushers” romanticized as a symbol of prosperity. Over time, however, these gushers became associated with the destruction of materials, human and environmental impacts, and a loss of marketable resources, leading to development of well control technologies.

Early Kick Detection: Testing New Concepts

After the 2010 subsea blowout of the Macondo well that resulted in 11 deaths and the worst oil spill in US history, early kick detection technology found itself at the top of the wish list for regulators and offshore companies seeking to avoid similar accidents. The National Commission on the BP Deepwater Horizon Oil Spill concluded that the crew lacked both training and the technology to recognize the critical signs that a kick was occurring.

New Kick Detection System Provides Early Warnings for Safer Drilling

The perception of oil and gas well control has evolved over the last century. In the late 1800s and early1900s, blowouts were held in high esteem, with “gushers” romanticized as a symbol of prosperity. Over time, however, these gushers became associated with the destruction of materials, human and environmental impacts, and a loss of marketable resources, leading to development of well control technologies.

Kicks provide the first indication that a well is becoming unstable. A kick can start as a slow leak from a pressured formation into the wellbore, but the flow increases as the influx of lower density reservoir fluid reduces the hydrostatic pressure exerted by the drilling fluid at the source of the flow. This causes the well to become underbalanced, requiring intervention for the operator to regain control. Failure to regain control usually results in a blowout.

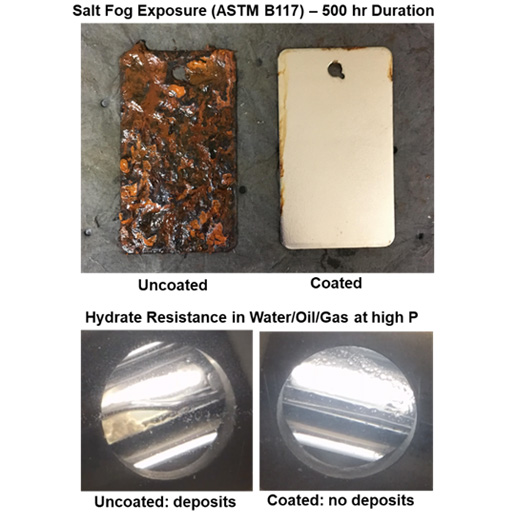

Medical Imaging Equipment Provides an Inside Look at Oil and Gas Well Cements

Strength and stability of cements are critical in protecting the environment from leaks and spills wherever drills penetrate the earth in search of oil and gas. But what types of cement work best under the extreme conditions encountered in oil and gas wells, and what adjustments can be made to increase safety during oil and gas exploration and production on land and at sea? NETL’s work on foamed cement is providing the answers.

NETL researchers polled industry to identify cement integrity issues after the 2010 Deepwater Horizon oil spill in the Gulf of Mexico, and the results led to an intensified effort at NETL to understand how variations in the structure of foamed cements impact wellbore effectiveness.

BLOSOM: ‘what if’ technology rapidly simulates offshore oil spills

New software developed by scientists in the US could prevent future hydrocarbon spills and accelerate the response to those that do occur. The team behind the technology explains more.

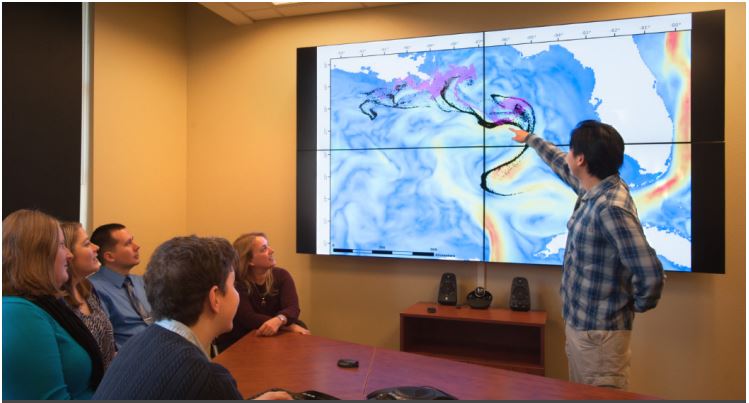

GAIA and the NETL Supercomputer Create Cutting-Edge Modeling Facility

As hydrocarbon exploration pushes into more remote and extreme environments to meet increasing energy needs, it is vital to keep developing technology and risk assessment methods in order to keep pace with the growing energy demand. In order to support risk reduction efforts, spatio-temporal and geostatistical approaches to technology development are being used to detect data trends, reduce geologic uncertainty, identify knowledge gaps, and evaluate environmental risks for carbon storage and hydrocarbon-related systems such as geologic carbon storage, and conventional and unconventional hydrocarbons. At NETL, top-of-the-line facilities enable the advanced computational capacities and collaborative workspaces needed to create the cutting-edge modeling tools.

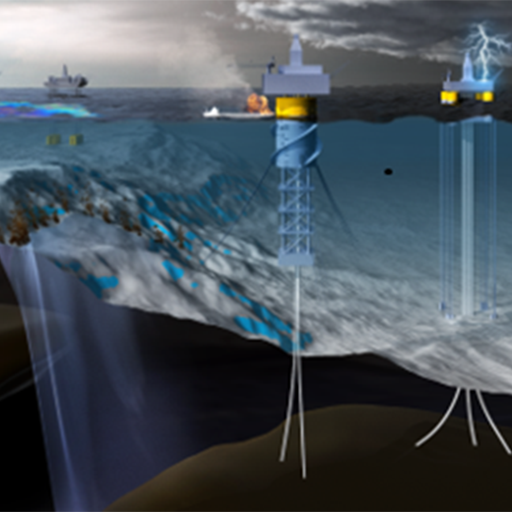

Combatting Offshore Drilling and Production Risks

For decades, the Gulf of Mexico (GOM) basin energy reserves have been an important domestic source of natural gas and crude oil. These resources will continue to play a critical role in meeting U.S. energy needs, provided they’re produced while effectively addressing environmental concerns. Science-based decision making, risk reduction, and identifying technology gaps are essential to responsibly developing offshore hydrocarbon resources.

OTC 2015: NETL highlights blowout, spill model

At the Offshore Technology Conference in Houston, researchers and scientists from the US Department of Energy’s National Energy Technology Laboratory (NETL) were on-hand to discuss the Blowout and Spill Occurrence Model (BLOSOM).

Part of NETL’s offshore energy resources research portfolio, BLOSOM is an integrated data and modeling system designed to simulate offshore oil spills resulting in well blowouts in water depths of 500 to 5,000 ft (152 to 1,524 m). NETL said the system can help with risk assessment; aids in the prevention of future spills; and also serves as a tool for response planning.

Nexus of Knowledge

In May 2010—nearly two weeks after the Macondo tragedy—the National Incident Command, in charge of the continuing emergency response efforts to halt the Deepwater Horizon oil spill, turned to U.S. scientists. The Flow Rate Technical Group, a diverse collection of scientists and engineers from 11 federal laboratories, universities and research institutions, including the U.S. Department of Energy’s (DOE’s) National Energy Technology Laboratory (NETL), was assembled to establish an accurate estimate of flow rate that was being discharged into the Gulf of Mexico. This mission required efficient and timely access to data, analytical tools and coordination capabilities to effectively handle the challenges associated with this multiorganization collaboration.

Location, Location, Location: An Oil Spill Comparison

Understanding the risks associated with offshore oil exploration and production is key to preventing oil spills that jeopardize wildlife and mankind. To determine what elements are most important to reducing the potential risks, researchers conducted a baseline study comparing the two largest single source oil spills in U.S. history: the Exxon Valdez tanker in Prince William Sound, Alaska, and the Deepwater Horizon oil rig in the Macondo prospect in the Gulf of Mexico. Jennifer Bauer, a Geospatial Analyst at NETL, worked on the project. “We started looking at the spills, comparing cleanup efforts to their impacts, and what we found that wasn’t already discussed in the literature, was that location matters. The length and duration of environmental and social community impacts varied based on where the spill occurred.”

Moving forward: Macondo five years later

The ecological, financial and emotional fall-out from the Macondo catastrophe was enormous. But learning and healing are well underway five years later. Regulatory agencies have been overhauled to better monitor industry activity. New technologies have come to the fore that make deepwater drilling safer. Consortia have been formed to develop spill response and containment strategies.

Offshore Industry Gets a Fresh Look at Foamed Cement

An ongoing research project started nearly 3 years ago by the US Department of Energy’s National Energy Technology Laboratory (NETL) is shedding new light on what really happens to foamed cement as it is pumped deep down offshore wells during completions.

The genesis of the research was the 2010 subsea blowout of the Macondo well in the US Gulf of Mexico (GOM) that destroyed the Deepwater Horizon drilling rig and claimed 11 lives. In the aftermath, the industry faced tough questions about the limits of its technology and the US government tapped NETL to improve the safety of offshore development.

Finding Answers To ‘What If?’

As offshore hydrocarbon exploration moves into deeper and more remote waters, the uncertainties associated with the safe development and production from strata located more than 3,050 m (10,000 ft) below the seafloor increase significantly. These challenges are found in the subsurface—like extreme reservoir temperatures, pressures and fluids—or in manmade equipment and materials. And every year—like countless spring breakers before her—Mother Nature finds the Gulf Coast in the summer months to be the perfect vacation destination. Unfortunately, she packs an impressive one-two combination of tropical storms and hurricanes that can leave offshore engineering marvels punch drunk and their operators with nasty hangovers. If only we could find some way to accurately divine the future to prevent and respond to such challenges.

Oil Tests at Extreme Conditions Yield New Data For Reservoir Modeling

Drilling in the extremely deep waters of the US Gulf of Mexico has revealed huge oil reservoirs, and gaps in the industry’s capabilities.

While much attention has gone toward creating high-performance equipment to develop and produce oil from high-pressure/high-temperature (HP/HT) formations such as the Lower Tertiary, researchers around the world have been quietly working on measuring how oil behaves under those extreme conditions.