New Kick Detection System Provides Early Warnings for Safer Drilling

The perception of oil and gas well control has evolved over the last century. In the late 1800s and early1900s, blowouts were held in high esteem, with “gushers” romanticized as a symbol of prosperity. Over time, however, these gushers became associated with the destruction of materials, human and environmental impacts, and a loss of marketable resources, leading to development of well control technologies.

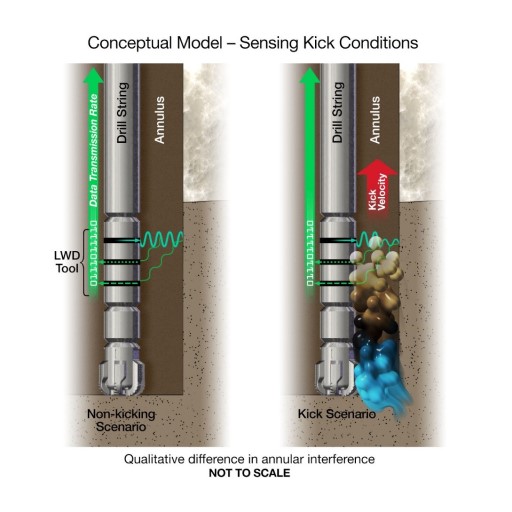

Kicks provide the first indication that a well is becoming unstable. A kick can start as a slow leak from a pressured formation into the wellbore, but the flow increases as the influx of lower density reservoir fluid reduces the hydrostatic pressure exerted by the drilling fluid at the source of the flow. This causes the well to become underbalanced, requiring intervention for the operator to regain control. Failure to regain control usually results in a blowout.

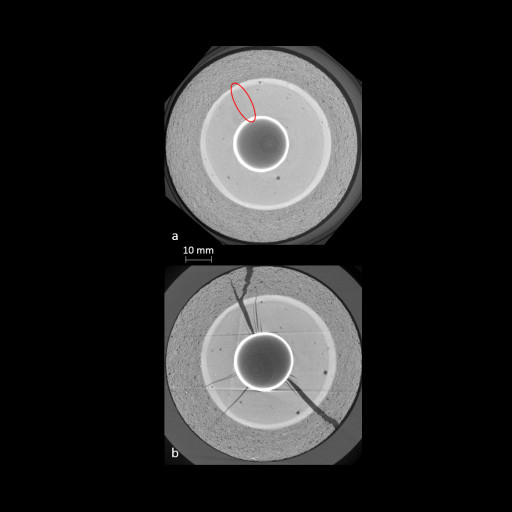

Medical Imaging Equipment Provides an Inside Look at Oil and Gas Well Cements

Strength and stability of cements are critical in protecting the environment from leaks and spills wherever drills penetrate the earth in search of oil and gas. But what types of cement work best under the extreme conditions encountered in oil and gas wells, and what adjustments can be made to increase safety during oil and gas exploration and production on land and at sea? NETL’s work on foamed cement is providing the answers.

NETL researchers polled industry to identify cement integrity issues after the 2010 Deepwater Horizon oil spill in the Gulf of Mexico, and the results led to an intensified effort at NETL to understand how variations in the structure of foamed cements impact wellbore effectiveness.

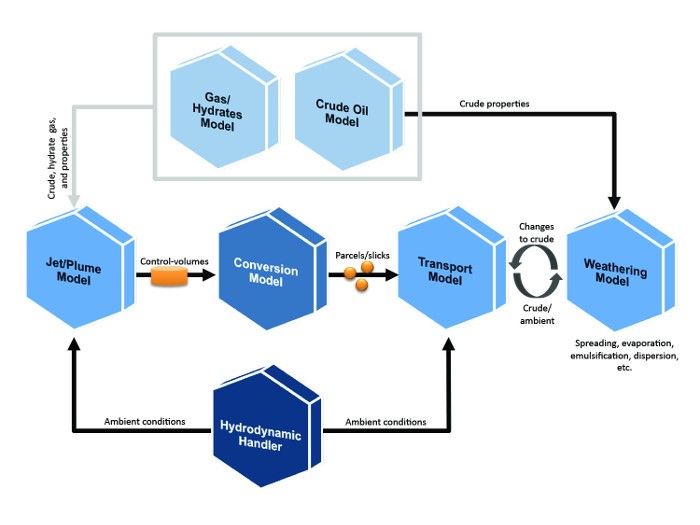

BLOSOM: ‘what if’ technology rapidly simulates offshore oil spills

New software developed by scientists in the US could prevent future hydrocarbon spills and accelerate the response to those that do occur. The team behind the technology explains more.

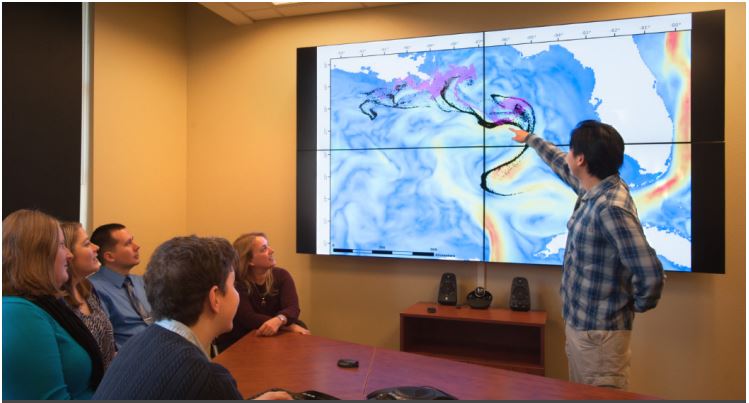

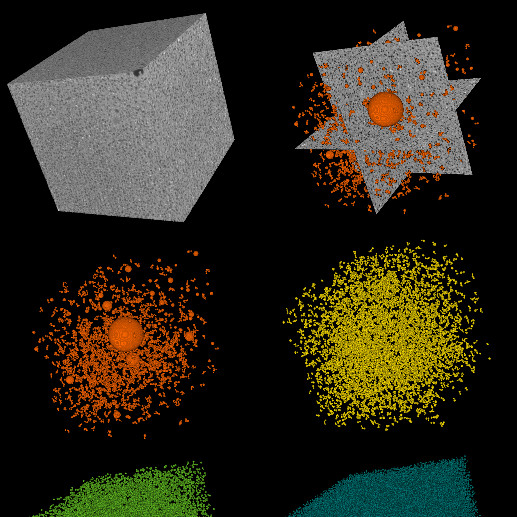

GAIA and the NETL Supercomputer Create Cutting-Edge Modeling Facility

As hydrocarbon exploration pushes into more remote and extreme environments to meet increasing energy needs, it is vital to keep developing technology and risk assessment methods in order to keep pace with the growing energy demand. In order to support risk reduction efforts, spatio-temporal and geostatistical approaches to technology development are being used to detect data trends, reduce geologic uncertainty, identify knowledge gaps, and evaluate environmental risks for carbon storage and hydrocarbon-related systems such as geologic carbon storage, and conventional and unconventional hydrocarbons. At NETL, top-of-the-line facilities enable the advanced computational capacities and collaborative workspaces needed to create the cutting-edge modeling tools.

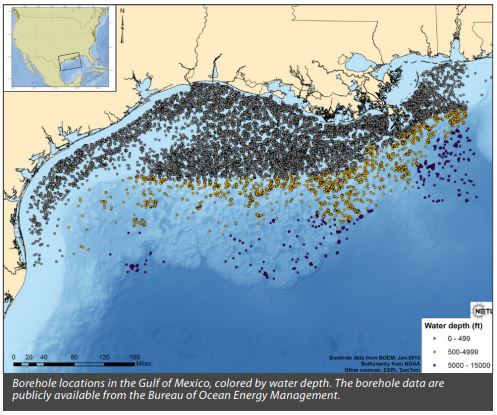

Combatting Offshore Drilling and Production Risks

For decades, the Gulf of Mexico (GOM) basin energy reserves have been an important domestic source of natural gas and crude oil. These resources will continue to play a critical role in meeting U.S. energy needs, provided they’re produced while effectively addressing environmental concerns. Science-based decision making, risk reduction, and identifying technology gaps are essential to responsibly developing offshore hydrocarbon resources.

OTC 2015: NETL highlights blowout, spill model

At the Offshore Technology Conference in Houston, researchers and scientists from the US Department of Energy’s National Energy Technology Laboratory (NETL) were on-hand to discuss the Blowout and Spill Occurrence Model (BLOSOM).

Part of NETL’s offshore energy resources research portfolio, BLOSOM is an integrated data and modeling system designed to simulate offshore oil spills resulting in well blowouts in water depths of 500 to 5,000 ft (152 to 1,524 m). NETL said the system can help with risk assessment; aids in the prevention of future spills; and also serves as a tool for response planning.

Nexus of Knowledge

In May 2010—nearly two weeks after the Macondo tragedy—the National Incident Command, in charge of the continuing emergency response efforts to halt the Deepwater Horizon oil spill, turned to U.S. scientists. The Flow Rate Technical Group, a diverse collection of scientists and engineers from 11 federal laboratories, universities and research institutions, including the U.S. Department of Energy’s (DOE’s) National Energy Technology Laboratory (NETL), was assembled to establish an accurate estimate of flow rate that was being discharged into the Gulf of Mexico. This mission required efficient and timely access to data, analytical tools and coordination capabilities to effectively handle the challenges associated with this multiorganization collaboration.

Location, Location, Location: An Oil Spill Comparison

Understanding the risks associated with offshore oil exploration and production is key to preventing oil spills that jeopardize wildlife and mankind. To determine what elements are most important to reducing the potential risks, researchers conducted a baseline study comparing the two largest single source oil spills in U.S. history: the Exxon Valdez tanker in Prince William Sound, Alaska, and the Deepwater Horizon oil rig in the Macondo prospect in the Gulf of Mexico. Jennifer Bauer, a Geospatial Analyst at NETL, worked on the project. “We started looking at the spills, comparing cleanup efforts to their impacts, and what we found that wasn’t already discussed in the literature, was that location matters. The length and duration of environmental and social community impacts varied based on where the spill occurred.”

Moving forward: Macondo five years later

The ecological, financial and emotional fall-out from the Macondo catastrophe was enormous. But learning and healing are well underway five years later. Regulatory agencies have been overhauled to better monitor industry activity. New technologies have come to the fore that make deepwater drilling safer. Consortia have been formed to develop spill response and containment strategies.

Offshore Industry Gets a Fresh Look at Foamed Cement

An ongoing research project started nearly 3 years ago by the US Department of Energy’s National Energy Technology Laboratory (NETL) is shedding new light on what really happens to foamed cement as it is pumped deep down offshore wells during completions.

The genesis of the research was the 2010 subsea blowout of the Macondo well in the US Gulf of Mexico (GOM) that destroyed the Deepwater Horizon drilling rig and claimed 11 lives. In the aftermath, the industry faced tough questions about the limits of its technology and the US government tapped NETL to improve the safety of offshore development.

Finding Answers To ‘What If?’

As offshore hydrocarbon exploration moves into deeper and more remote waters, the uncertainties associated with the safe development and production from strata located more than 3,050 m (10,000 ft) below the seafloor increase significantly. These challenges are found in the subsurface—like extreme reservoir temperatures, pressures and fluids—or in manmade equipment and materials. And every year—like countless spring breakers before her—Mother Nature finds the Gulf Coast in the summer months to be the perfect vacation destination. Unfortunately, she packs an impressive one-two combination of tropical storms and hurricanes that can leave offshore engineering marvels punch drunk and their operators with nasty hangovers. If only we could find some way to accurately divine the future to prevent and respond to such challenges.

Oil Tests at Extreme Conditions Yield New Data For Reservoir Modeling

Drilling in the extremely deep waters of the US Gulf of Mexico has revealed huge oil reservoirs, and gaps in the industry’s capabilities.

While much attention has gone toward creating high-performance equipment to develop and produce oil from high-pressure/high-temperature (HP/HT) formations such as the Lower Tertiary, researchers around the world have been quietly working on measuring how oil behaves under those extreme conditions.