Overview

This project validates a new hydrate-phobic coating for deepwater well operations, through testing under a variety of flow conditions, to improve safety, cost, and component life.

As oil and gas production wells mature, the risk of gas hydrate blockages in flowlines can become hard to manage, limiting the life of the field and incurring prohibitive costs. In order to both reduce costs of inhibitor injection and prevent safety hazards to personnel and equipment caused by flowline blockages, researchers are exploring technologies that can extend field life and minimize product loss in a safer, more cost-effective manner.

This project aims to design, test, and validate robust pipeline coatings to prevent and minimize gas hydrate deposits in subsea oil flowlines, addressing major flow assurance problems that continue to plague deepwater field operations. A coating capable of preventing gas hydrate deposition would represent a breakthrough over the current state-of-the-art, mitigating the severe production, environmental, and safety issues that this deposition can cause during operation.

Approach

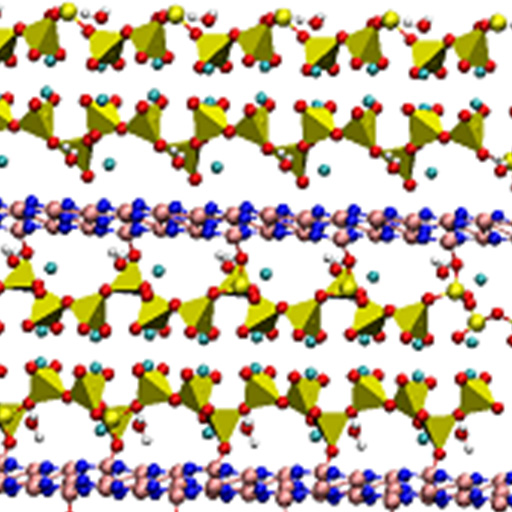

Low-surface energy coating materials that can be applied in situ to operational pipelines represent a critical need for industry. A novel coating developed during a previous DOE-sponsored collaboration between The Colorado School of Mines (CSM) Center for Hydrate Research (Golden, CO) and Oceanit Laboratories (Honolulu, HI) showed promise in preventing hydrate deposition in small-scale apparatuses. This project will advance and scale-up this concept by testing and validating second-generation hydrate-phobic coatings in larger multiphase flow systems.

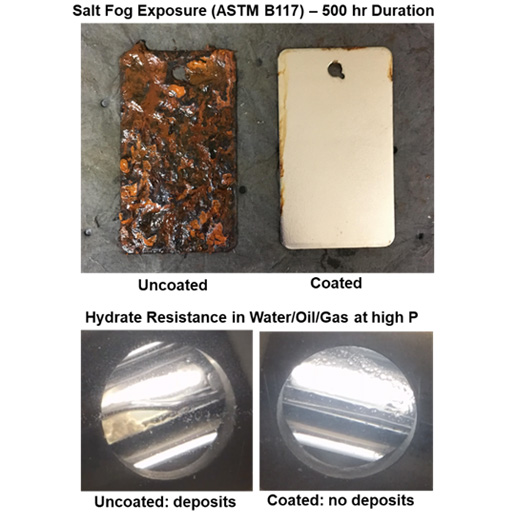

CSM and Oceanit Laboratories will test different coatings for their hydrate repellency and long-term survivability. To do this, CSM has extended its deposition loop system to expand coating testing under a variety of flow conditions; baseline testing was performed using a single-pass flow loop system, with the capability to test varying corrosion levels, coatings, and bulk phase fluid compositions. The loop system will be used throughout to test the effectiveness of these advanced coatings during both steady-state and transient operations. Oceanit has created coupons and pipeline coatings to demonstrate its omniphobic coating in CSM’s rocking-cell apparatus and larger-scale deposition loop. The coating material development and testing has demonstrated the coating has diverse chemical resistance and long-term survivability.

CSM and Oceanit have demonstrated the omniphobic coating’s ability to reduce and mitigate hydrate adhesion and deposition while simultaneously preventing corrosion, and reducing wax and asphaltene deposition. Further large-scale tests are underway, simulating field conditions for hydrate deposition mitigation under transient conditions. In addition, longer-scale testing for wax and asphaltene deposition mitigation are also underway to test and validate the robustness of the coating.

Expected Outcome

The successful development of a robust pipeline coating to prevent flowline blockages caused by gas hydrates would result in significant savings for pipeline operators, whose current mitigation efforts can exceed $1 million in costs for a single mile of pipeline. The existing methods used to avoid gas hydrate deposition have become increasingly untenable from both an environmental and economic standpoint, and this new coating will provide flow assurance, limit catastrophic blowout, and minimize smaller sustained leaks.

There is a pressing need within the industry for an approach that facilitates well production where traditional methods for limiting hydrate buildup are unfeasible. This research represents a novel, cost-effective solution to these challenges, offering a major fundamental breakthrough in gas hydrate science and engineering.

Research Products

Offshore Technology Conference

Offshore Technology Conference (OTC), OTC 2019 (paper presented)

OTC 2020 (abstract accepted); NACE paper submitted.

Explore research products that are related to this project.

Images

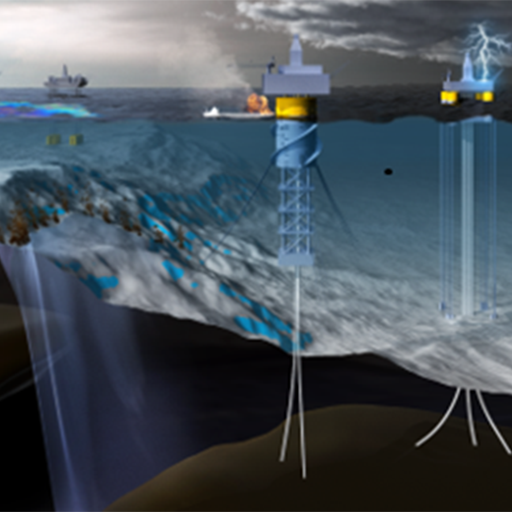

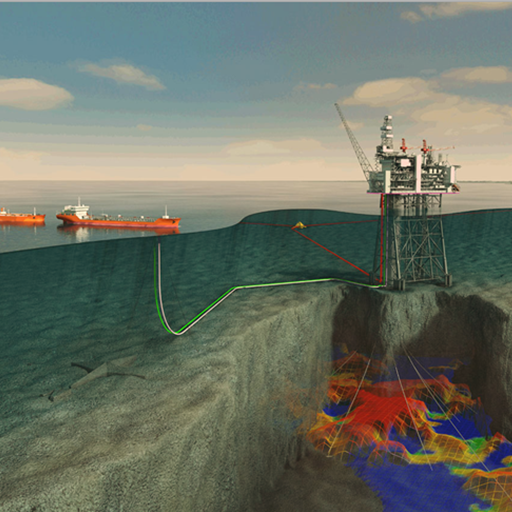

Examples of the functional coatings being developed for in-situ application to mitigate corrosion and flow assurance solids deposition, including gas hydrates, waxes, and asphaltenes are illustrated in Figure 1.

Contacts

William Fincham

Federal Project Manager

Jared Ciferno

Technology Manager

Carolyn Koh

Principal Investigator

Maria Vargas

Team Supervisor

Nicholas Anderson

Contract Specialist