Overview

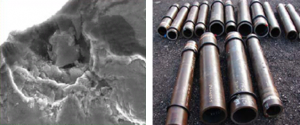

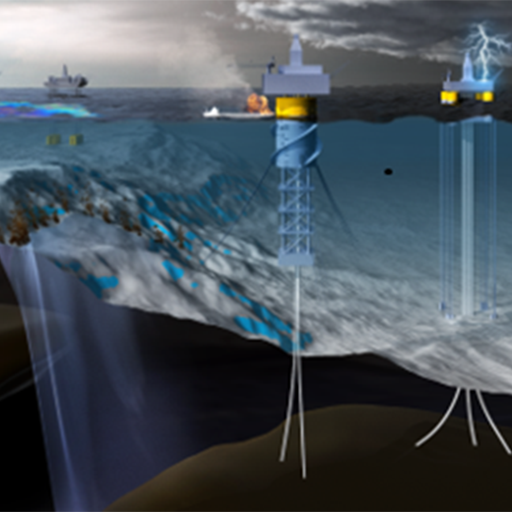

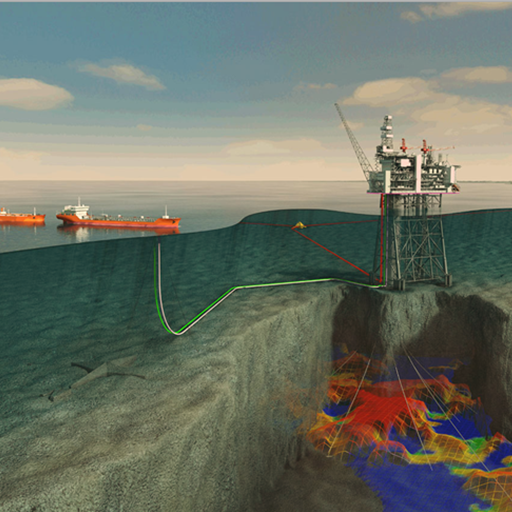

Extreme offshore hydrocarbon operations require strong, durable, and corrosion resistant materials. Metallic components are used in risers, umbilicals, drill pipe, pipelines, blow out preventers, and numerous other components associated with offshore drilling in both the water column and subsurface systems. Ensuring the lasting performance and the appropriate use of these materials is a vital step in addressing the economic, environmental, and safety concerns related to efficient offshore production and risk prevention. Unfortunately, materials used in offshore oil and natural gas operations have reached their limit of effectiveness in terms of operating environment. New materials must be designed.

This project evaluated the most commonly used alloys in these applications to characterize their limitations and appropriate uses. The project also identified environmental and mechanical factors that affect metal performance in extreme offshore environments.

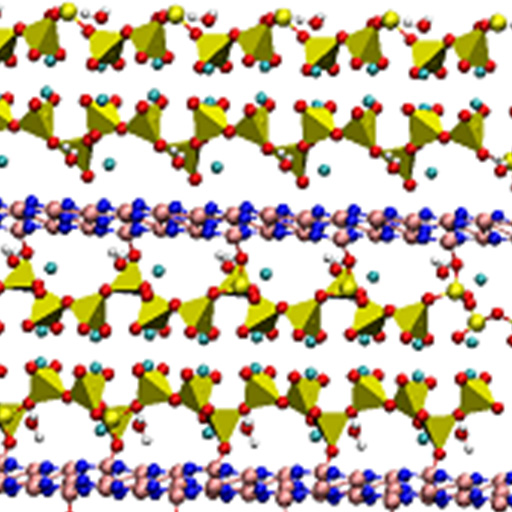

The development of material information databases to catalog and analyze baseline physical and mechanical behavior, as well as environment specific property performance of basic materials, was an important element of this project. This work reduced the relative risks for critical components in offshore environments by using data analytics and other large data strategies to determine expected materials lifespan under different operating scenarios. A Technical Report Series publication presents findings on Fatigue Crack Growth Rate of UD-165 in Sour Environments.

Approach

This project seeks to identify the failure mechanisms and rates of material degradation for critical components in offshore drilling by basing determinations on observed/reported behavior in the field. However, as there is limited publicly available data on the performance of these materials under extreme offshore conditions, the study will be augmented with experimental research on materials performance under simulated extreme conditions. To date, this study has successfully evaluated the strength/corrosion potential of the most common alloys used in extreme offshore drilling under in situ conditions (pressure, temperature, hydrogen sulfide, etc.). Work is ongoing in the development of a pit/fatigue model for the assessment of catastrophic failure potential of these metallic components. NETL is also evaluating new alloys (e.g., nickel-based alloys as a structural material or as a cladding onto steel) and surface treatments (e.g., hammer peening) for ultra-deep well environments. A recent Technical Report Series publication presents findings on Fatigue Crack Growth Rate of UD-165 in Sour Environments.

Outcomes

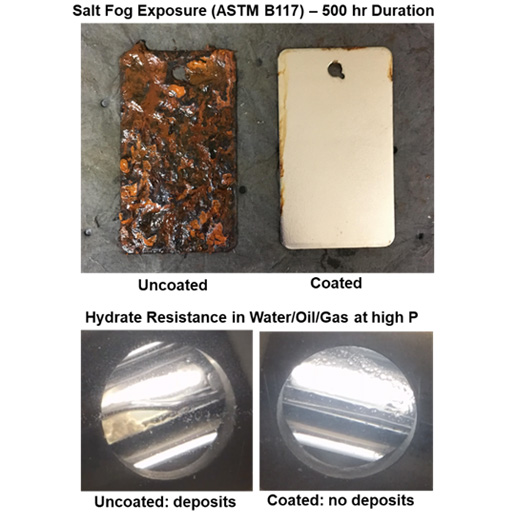

This project identified the failure mechanisms and rates of material degradation for critical components in offshore drilling by using observed/reported behavior. The research successfully evaluated the strength/corrosion potential of the most common alloys used in extreme offshore drilling under in-situ conditions. The researchers also evaluated new alloys and surface treatments for ultra-deep well environments.

The primary outcome of this project was the knowledge gained of the environmental and mechanical factors that affect metal performance. Other key outcomes included:

- An understanding of the fatigue behavior of high-strength steels for the next generation of ultra-deepwater risers.

- Knowledge about how modifying the surface high-strength steel and nickel superalloys improves the corrosion and fatigue performance components, especially for application in failure-prone component locations.

- Data on the effect of environmental factors and the impact of localized corrosion on fatigue crack initiation and propagation in drill string alloys.

- Understanding of the corrosion behavior of alloys in simulated sour service environments as functions of pH, temperature, and hydrogen sulfide concentration, and determining the role of hydrogen sulfide as a catalyst on the corrosion degradation process.

- Reference electrodes for use in high pressure/high temperature systems for corrosion sensors for down-hole application.

The fatigue crack growth rate and fracture toughness of ultra-high strength steel (UD-165) and several nickel superalloys (IN 718, IN 625, IN 725) were determined under offshore, deep-well environmental conditions. The effect of surface modification (e.g., hammer peening) were investigated for IN 718 for aggressive environmental conditions.

Research Products

Materials Engineering and Manufacturing Onsite Research

R&D Fact Sheet

October 2019

https://www.netl.doe.gov/node/3411

NETL Geomaterials Research Facilities

R&D Fact Sheet

April 2019

Christina Lopano, Principal Investigator

https://www.netl.doe.gov/node/3417

Effects of CO2 and H2S on Corrosion of Martensitic Steels in Brines at Low Temperature

Corrosion 2018, 74, 276–287

Feng, R.; Beck, J. R.; Hall, D. M.; Buyuksagis, A.; Ziomek-Moroz, M.; Lvov, S. N.

March 2018

https://www.corrosionjournal.org/doi/abs/10.5006/2406?journalCode=corr

https://doi.org/10.5006/2406

Data Analytics for Alloy Qualification

NETL-PUB-21550; U.S. Department of Energy, National Energy Technology Laboratory: Pittsburgh, PA, March 2018

Krishnamurthy, N.; Maddali, S.; Verma, A.; Bruckman, L.; Carter, J.; French, R.; Romanov, V.; Hawk, J. A.

March 2018

https://www.osti.gov/biblio/1456238-data-analytics-alloy-qualification

Corrosion Performance of Ultra-High Strength Low Alloy Steel in CO2/H2S-containing Brines

Presented at the 13th Annual Hydrogen Embrittlement Workshop, ASTM Committee F07.04 on Hydrogen Embrittlement, Atlanta, GA, Nov 16, 2017.

Ziomek-Moroz, M.; Hawk, J. A.; Thodla, R.; Lvov, S.

Application of Data Science to the Study and Design of 9-12% Cr Steel

Presented at the Materials Science and Technology 2017, Data and Tools for Materials Discovery and Design, Pittsburgh, PA, Oct 8–12, 2017.

Verma, A. K.; Hawk, J. A.; Bruckman, L.; Romanov, V.; French, R. H.; Carter, J. L. W.

Application of Data Science to the Study and Design of 9-12% Cr Steel

Poster presented at the 3rd Annual Data and Life Sciences Collaboration and Symposium, Case Western Reserve University, Cleveland, OH, Aug 3–4, 2017.

Verma, A. K.; Hawk, J. A.; Bruckman, L.; Romanov, V.; French, R. H.; Carter, J. L. W.

Application of Data Science to the Study and Design of 9–12% Cr Steel

Poster presented at the Physical Metallurgy, Gordon Research Conference, Biddeford, ME, July 23–28, 2017.

Verma, A. K.; Hawk, J. A.; Bruckman, L.; Romanov, V.; French, R. H.; Carter, J. L. W.

Rapid Design, Development and Deployment of Materials for Extreme Environments

Proceedings of the 2017 TechConnect World Innovation Conference & Expo, National Harbor, MD, May 14–17, 2017; pp. 367–370

Mollot, D.; Cedro, V.; Hawk, J. A.; Conrad, R.; Alman, D. E.; Powell, C.

May 2017

https://www.techconnectworld.com/World2017/about/ConferenceProceedings.html

Rapid Design, Development and Deployment of Materials for Extreme Environments

Presented at the 2017 TechConnect World Innovation Conference & Expo, Materials Informatics & Design Innovation, National Harbor, MD, May 14–17, 2017.

Mollot, D.; Cedro, V.; Hawk, J.A.; Conrad, R.; Alman, D. E.; Powell, C.

Segmentation of 9Cr Steel Samples Based on Composition and Mechanical Property

Presented at the American Physical Society (APS) March Meeting, New Orleans, LA, Mar 13–17, 2017.

Krishnamurthy, N.; Maddali, S.; Hawk, J.; Romanov, V.

High Strength Nickel-Based Alloys for HPHT Applications

Presented at the Energy Materials 2017: Materials for Oil and Gas and AMREE Oil & Gas III, Hydrogen Effects on Materials in Energy, San Diego, CA, Feb 26–Mar 2, 2017.

Thodla, R.; Liu, C.; Hawk, J.A.; Ziomek-Moroz, M.; Rozman, K. A.

Statistical Analysis of Heritage Data of 9-12% Cr Steels, Using a Robust, Open Source, Data Analytics Design Approach

Presented at the MS&T16 Technical Meeting & Exhibition, Salt Lake City, UT, Oct 23–28, 2016.

Verma, A. K.; Elsaeti, M.; Bruckman, L. S.; Hawk, J. A.; Romanov, V.; French, R. H.; Carter, J. W.

Electrochemical Corrosion of Ultra-High Strength Carbon Steel in Alkaline Brines Containing Hydrogen Sulfide

Electrochimica Acta 2016, 212, 998–1009

Feng, R.; Beck, J. R.; Ziomek-Moroz, M.; Lvov, S.

September 2016

http://www.sciencedirect.com/science/article/pii/S0013468616315754

Characterizing the Behavior of Metal-Based Systems Used for Control Devices in Extreme Environments

Presented at the 2016 Mastering the Subsurface through Technology Innovation and Collaboration: Carbon Storage and Oil and Natural Gas Technologies Review Meeting, Pittsburgh, PA, Aug 16–18, 2016.

Hawk, J. A.

Fatigue and Fracture of Nickel Superalloys for Sour Service Environments in Accordance with API 17TR8

Presented at the NACE International Portland Section Meeting, Albany, OR, April 14, 2016.

Rozman, K. A.; Hawk, J. A.; Ziomek-Moroz, M.; Thodla, R.

Sour Service Fatigue and Fracture Behavior of High Strength Steels

Presented at the NACE Corrosion 2016 Conference & Exposition, Vancouver, BC, Canada, March 6–10, 2016.

Thodla, R.; Hawk, J. A.; Ziomek-Moroz, M.

Corrosion Behavior of Ultra-high Strength Drilling Steel in Alkaline Brines Containing Hydrogen Sulfide at High Temperature

Paper No. 7657; NACE International Corrosion 2016 Conference and Expo; NACE: Houston, TX, 2016

Ziomek-Moroz, M.; Feng, R.; Beck, J. R.; Hall, D. M.; Wolfe, I.; Buyuksagis, A.; Lvov, S. N.

March 2016

https://www.researchgate.net/publication/301895532_Corrosion_Behavior_of_Ultra-high_Strength_Drilling_Steel_in_Alkaline_Brines_Containing_Hydrogen_Sulfide_at_High_Temperature

Relationship between Localized Corrosion and Stress Corrosion Cracking of Nickel Based Alloys

Presented at the NACE Corrosion 2016 Conference & Exposition, Vancouver, BC, Canada, March 6–10, 2016.

Thodla, R.; Cao, L.; Hawk, J. A.; Ziomek-Moroz, M.

Effects of CO2 and H2S on Corrosion of Martensitic Steels in NaCl at Low Temperature

Paper No. 7659; NACE International Corrosion 2016 Conference and Expo; NACE: Houston, TX, 2016

Ziomek-Moroz, M.; Feng, R.; Beck, J. R.; Hall, D. M.; Buyuksagis, A.; Lvov, S. N.

March 2016

https://www.researchgate.net/publication/301895534_Effects_of_CO2_and_H2S_on_Corrosion_of_Martensitic_Steels_in_NaCl_at_Low_Temperature

Sour Service Fatigue and Fracture Behavior of High Strength Steels

Paper No. 7183; NACE International Corrosion 2016 Conference and Expo; NACE: Houston, TX, 2016

Thodla, R.; Cao, L.; Hawk, J.; Ziomek-Moroz, M.

March 2016

https://edx.netl.doe.gov/dataset/nace-2016-paper-7183/resource_download/9af3c844-e0a1-419d-8214-e996cad88cfd

Relationship between Localized Corrosion and Stress Corrosion Cracking of Nickel Based Alloys in HPHT Oil and Gas Environments

Paper No. 7113; NACE International Corrosion 2016 Conference and Expo; NACE: Houston, TX, 2016

Thodla, R.; Cao, L.; Hawk, J.; Ziomek-Moroz, M.

2016

https://edx.netl.doe.gov/dataset/nace-2016-paper-7113/resource_download/6d54a15d-fdc2-4a9d-af53-f93234d12cbc

The Finite Body Triangulation: Algorithms, Subgraphs, Homogeneity Estimation and Application

Journal of Microscopy

February 2016

https://doi.org/10.1111/jmi.12388

Corrosion Behavior of 13Cr Casing Steel in Cement-Synthetic Pore Solution Exposed to High Pressure CO2 and H2S

Electrochemical Society Transactions 2015, 69, 27–40.

Feng, R.; Beck, J. R.; Hall, D.; Ziomek-Moroz, M.; Lvov, S. N.

October 2015

http://ecst.ecsdl.org/content/69/26/27.abstract

Corrosion Behavior of casing Steels in Cement Synthetic Pore Solution Exposed to High Pressure CO2 and H2S

Presented at the 228th Electrochemical society Meeting, Phoenix, AZ, Oct 11–15, 2015.

Feng, R.; Beck, J.; Hall, D.; Lvov, S. N.; Bukyuksagis, A.; Ziomek-Moroz, M.

Explore research products that are related to this project.

See related Phase 2 projects.

Contacts

Jeff Hawk

Principal Investigator

Kelly Rose

Offshore Portfolio Lead

Roy Long

Offshore Portfolio Technical Manager

Effective Resource Development

Alexandra Hakala

Senior Fellow (Detail)

Geological & Environmental Systems

David Alman

Associate Director

Materials Engineering & Manufacturing