Overview

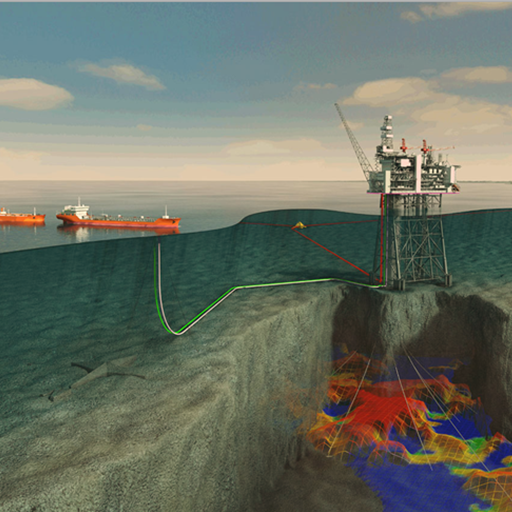

This project is focused on developing a numerical surrogate of an acoustic sensor like those used in logging-while-drilling (LWD) tools to develop multiphase flow data corresponding to a kick event. This activity, together with the Constraining Kick Signals with Multi-Phase Data project, provide a cost-effective path to develop data of the sensor response and corresponding conditions. A digital analog also allows for opportunities to assist in the conceptualization and design of a physical sensor, and act as a platform to explore its constraints and for optimization.

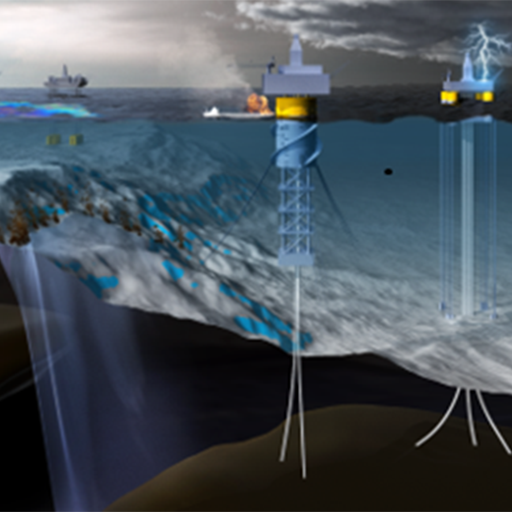

A kick refers to the onset of formation fluid flow into the wellbore and represents the first stage of a loss of well control. Not all kicks are serious events, but when left unabated the process may accelerate and result in a blowout (complete loss), which can result in the loss of life, lasting environmental damage, and substantial economic losses. The best opportunity to prevent a blowout is to suppress the kick as soon as possible after it initiates. To achieve this accurate and early kick detection and reporting is essential. Conventional kick detection methods (e.g., monitoring mud pit returns, monitoring fluid flowrates, monitoring wellbore pressure) rely on techniques that are uncertain, limited in their applicability (e.g., only useful to certain drilling stages), and/or delayed in their detection. Newer kick detection techniques use more certain detection methods, but are considered expensive.

A kick detection technique that is inexpensive and accurately conveys critical wellbore information in a timely manner provides a significant advantage over conventional methods for detecting and suppressing kicks. As identified in NETL’s patented Kick Technology, existing downhole geophysical sensors, like those used in LWD, offer an opportunity for near real-time monitoring of the bottom hole condition. Early kick detection serves not only as a safety management tool, but also as a tool for environmental management as only by avoiding kicks and potential blowouts can their environmental impacts be abated.

Beyond theory and anecdotal observations, how a kick affects downhole geophysical measurements used in LWD operations is not well understood. Many variables, such as fluid properties, flow properties, wellbore geometry, drilling conditions, and geologic properties, can affect the kick signal. Unfortunately, data from these geophysical signals, that can be easily used to not only identify but also to constrain and quantify properties related to kicks, (e.g., the type and volume of a kick) are not readily available. This effort seeks to numerically emulate this scenario enhancing and supplementing the experimental data from the Constraining Kick Signals with Multi-Phase Data project. This data may be used for development of a new kick detection and fingerprinting concept for preventing well blowouts.

Approach

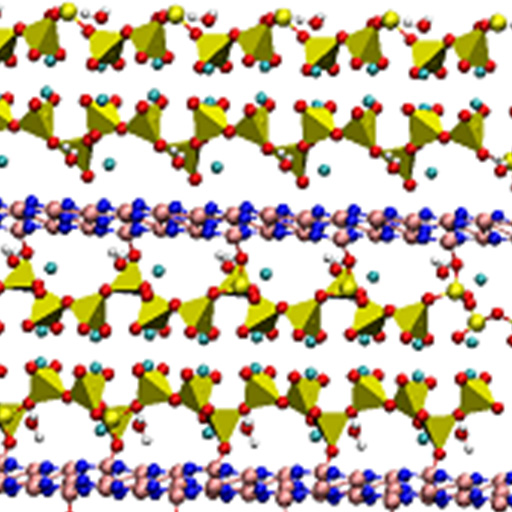

The current effort is focused on creating a digital twin LWD tool using a commercial Multiphysics CFD package. During this year the literature will be reviewed to develop a better understanding of acoustic modeling in general and the corresponding computational capabilities relevant to the problem of interest. This effort will determine appropriate modeling framework for exploring acoustic responses (e.g., velocity and attenuation) in the downhole environment. The initial CFD model will be developed including geometry creation and meshing of the environment. A preliminary set of simulations focusing on the effect of gas bubbles on the signal of the LWD tool will be run. A comparison with the data from the Constraining Kick Signals with Multi-Phase Data project will provide an opportunity to assess the model. While the model is anticipated to qualitatively capture the behavior observed in the experiment, the quantitative accuracy is unknown.

The next step will involve assessing the degree of quantitative mismatch and seek to improve any discrepancies. Physics that might be missing from the model and that can be readily incorporated will be addressed. This will be a cyclic process possibly calling for further model development to encompass additional physics. During this step the ability to extrapolate the model to different situations will be tested, such as, the ability to extend the model to different geometries.

Provided success in the former stages, the model will be used to explore different scenarios in the wellbore and to quantify the envelop (conditions/tolerances) for which current LWD tools are expected to detect kicks. Focus will be on using the refined digital twin logging tool to generate a “big data” database of sensor signals to develop, train, test, and improve the NETL algorithm technique for early kick detection.

Expected Outcome

A numerical surrogate of LWD sensor(s) will be developed using a commercial CFD package that can then be used to create a database of simulated signals corresponding to a kick event. The data developed will serve as a test bed for NETL’s kick detection method; a kick signature may be developed by compiling measurements for kick-drilling fluid combinations.

This effort will also serve to assist a separate but complementary experimental activity (Constraining Kick Signals with Multi-Phase Data), specifically with sensor design. The data procured from the experimental activity will be leveraged for validation of the present model. Pending validation, the proposed numerical effort will seek to better quantify the envelop (conditions and tolerances) for which the current tool can detect kicks. As needed, this effort will continue to explore tool optimization (geometry/design) for early kick detection.

Research Products

Research products are being developed and will be posted here as updates when publicly available.

Explore research products that are related to this project.