Overview

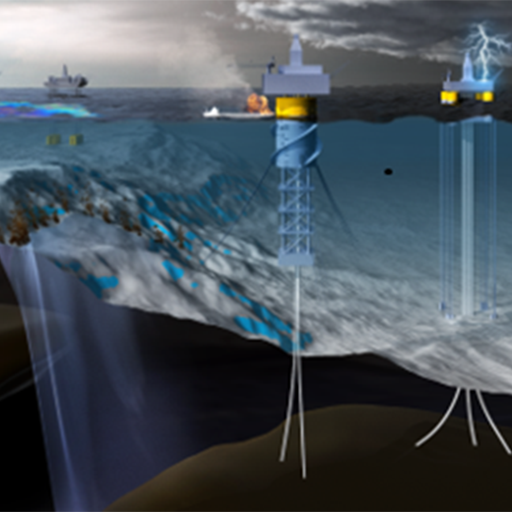

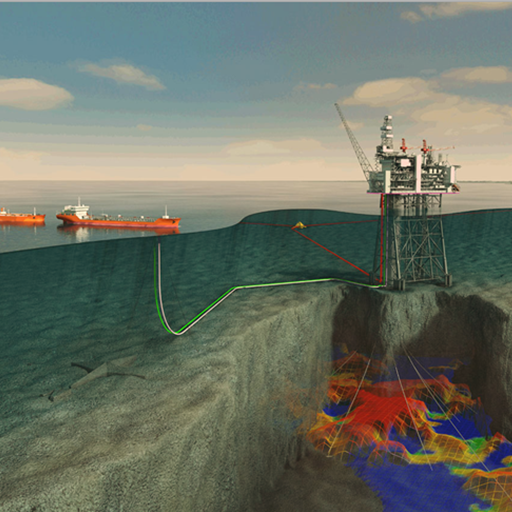

During petroleum and natural gas (PNG) production, deposits of mineral scales throughout the production facilities cause not only production losses, but also equipment damage, and enhanced corrosion leading to serious safety concerns. As oil, gas, and brine proceed from the formation to the surface, changes in the production fluid’s pressure and temperature cause certain dissolved salts to precipitate and coat production tubulars, casing, valves, pumps, and downhole safety equipment. As an extreme example, in a North Sea well, production fell from 30,000 B/D to zero in just 24 hours because of scaling.

While all wells are not vulnerable to such quick scaling, there is no question that scale formation, because of the associated costs and safety issues, is an urgent problem in the oil and gas industry. Reliable thermodynamic models and databases are not available for many species relevant to scaling at high pressure high temperature (HPHT) conditions. While scaling at temperatures below 150°C is relatively well studied, scaling at HPHT conditions, such as those typically encountered in offshore ultradeep reservoirs, is a significant challenge and is poorly understood.

This project is extending mineral scale predictions to HPHT conditions where current state-of-the art models significantly loose accuracy. The project has developed a research plan to use OLI Systems (OLI) Scale models (ScaleChem) to assist two scaling projects in progress. The ultimate objective of the project is to develop HPHT scale models that will be released to the public to be implemented into popular software such as OLI Studio: ScaleChem software, a commercial software originally developed by Shell and redeveloped by OLI to predict mineral scale scenarios. This will be completed by transferring the newly developed computer codes to OLI personnel. The new version of OLI software will then be available to be used in industry for proactive mitigation of scaling problems at HPHT conditions during oil and gas production.

Approach

A challenge and key step in scaling prediction is the simulation of scale-water equilibrium using thermodynamic models. But this is only possible if thermodynamic properties of all phases and components are known. Yet, previous studies reveal that reliable thermodynamic models and databases are not available for many species relevant to scaling at HPHT conditions. The best method to modify the state-of the art model to further reduce the number of empirical parameters will be identified.

A combination of theoretical, computational, and experimental approaches will be undertaken to address HPHT scaling problems. Initially, currently DOE-funded projects on scaling at NETL and the Stanford Linear Accelerator Center (SLAC) National Accelerator Laboratory will be reviewed and then the existing OLI ScaleChem software will be used to assist in designing and optimizing experiments. In parallel, the unique HPHT phase composition facility at NETL will be used to experimentally study thermodynamic properties relevant to scaling at HPHT conditions and visualize mineral scales by varying the temperatures and pressures. The necessary thermodynamic algorithm needed for simulating scaling in conditions representative of ultradeep offshore oil and natural gas reservoirs will then be developed. The objective is to implement this algorithm into OLI Studio: ScaleChem.

Expected Outcome

This newly developed software can then be used as the first step in the scale prevention for safe and reliable operation in the offshore oil and natural gas production in HPHT environments.

Research Products

A. Theoretical and Modeling Efforts

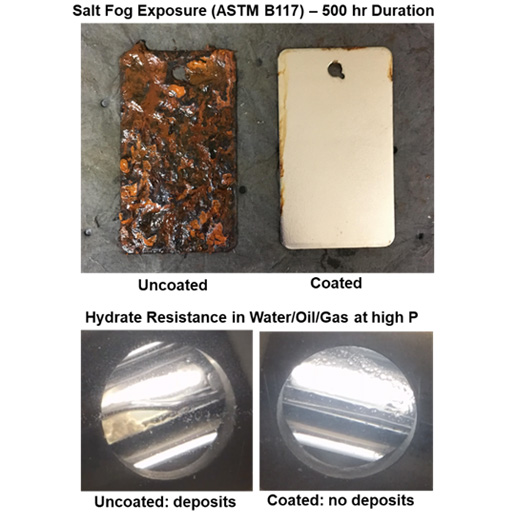

A new model based on molecular statistical thermodynamic expressions outperformed the previous state of the art in thermodynamic modeling. The pre-existing Helgeson-Kirkham Flowers (HKF) model consistently overpredicted solubility values for barite in HPHT environments, whereas this new model improved prediction accuracy by up to 2000% (Figure 1). The model successfully quantified the standard Gibbs energy of ionic and neutral species of aqueous species resulting from barite dissolution into water over a wide temperature range covering ambient conditions up to 500 °C. Standard Gibbs energy values of Ba2+(aq), SO42-(aq), BaSO4(aq) and BaSO4(s) were used to determine equilibrium constants for barite precipitation and ion association reactions. These two reactions were sufficient to model the solubility limit of barite in water in environments not previously possible.

Figure 1. Mineral scale solubility model improvements in HPHT conditions (500 to 1300 bar)

The new model and its applications have been presented at two technical meetings [1,2] and summarized in a book chapter [3].

- Gamwo, I. K., Hall, D.M., Lvov, S.N, Status of Modeling and Visual Observation of Mineral Scaling in High Temperature Aqueous Solutions, paper 276d, AIChE Virtual Annual Meeting, November 16-20, 2020.

- Gamwo, I. K., Hall, D.M., Lvov, S.N, Baled, H.O. Modeling Barium Sulfate Precipitation in High Temperature Systems based on Molecular Statistical Thermodynamics Model, paper 425c, AIChE Annual Meeting, Boston, MA, November 7-11, 2021.

- Hall, D.M., Lvov, S.N, Gamwo, I.K, Prediction of Barium Sulfate Deposition in Petroleum and Hydrothermal Systems, Solid–Liquid Separation Technologies: Applications for Produced Water, CRC Press Taylor & Francis, in press, 2022.

B. Experimental Efforts

We are developing a new solubility experimental capability at NETL. We designed a technique for high-temperature, high-pressure solubility measurements based on the experimental setup developed by Garcia (Garcia A. V. Measurement and Modelling of Scaling Minerals, Ph.D. Thesis, Technical University of Denmark, 2005). The new high-temperature, high-pressure mineral solubility experimental apparatus is being built at NETL in Pittsburgh and is projected to be completed in January 2022.

C. Collaboration Efforts with Experimental Groups

We completed a white paper on a collaborative effort between the experimental research group at SLAC National Accelerator Laboratory and the NETL-PSU modeling group to expedite and optimize their experimental studies. The white paper was submitted to seek the funding necessary to execute the tasks.

Prediction of Barium Sulfate Deposition in Petroleum and Hydrothermal Systems

Hall, D.M., Lvov, S.N, Gamwo, I.K, Prediction of Barium Sulfate Deposition in Petroleum and Hydrothermal Systems, Solid–Liquid Separation Technologies: Applications for Produced Water, CRC Press Taylor & Francis, in press, 2022.

Modeling Barium Sulfate Precipitation in High Temperature Systems based on Molecular Statistical Thermodynamics Model

Gamwo, I. K., Hall, D.M., Lvov, S.N, Baled, H.O. Modeling Barium Sulfate Precipitation in High Temperature Systems based on Molecular Statistical Thermodynamics Model, paper 425c, AIChE Annual Meeting, Boston, MA, November 7-11, 2021.

Status of Modeling and Visual Observation of Mineral Scaling in High Temperature Aqueous Solutions

Gamwo, I. K., Hall, D.M., Lvov, S.N, Status of Modeling and Visual Observation of Mineral Scaling in High Temperature Aqueous Solutions, paper 276d, AIChE Virtual Annual Meeting, November 16-20, 2020.

Explore research products that are related to this project.

Contacts

Isaac Gamwo

Principal Investigator

Kelly Rose

Co-Principal Investigator

Offshore Portfolio Lead

Roy Long

Offshore Portfolio Technical Manager

Effective Resource Development

Alexandra Hakala

Senior Fellow (Detail)

Geological & Environmental Systems

Philip Reppert

Associate Director

Geological & Environmental Systems