- High-quality fracture network map is essential to investigate the integrity of the reservoir for Carbon Capture Utilization and Storage (CCUS).

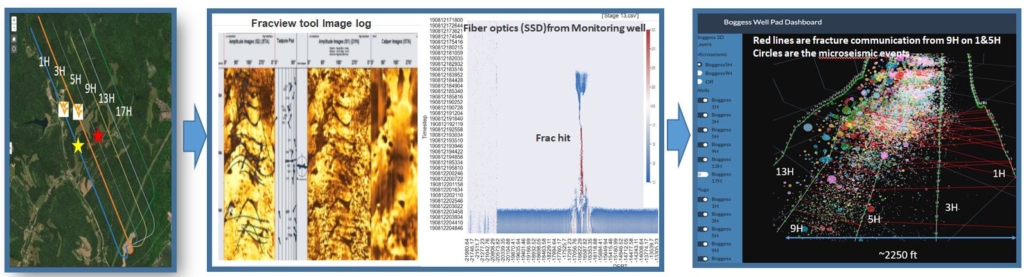

- We have developed a workflow to map and visualize the fracture network using Integration of data collected from actual field measurements including:

- Acoustic image logs: obtained from each well to identify the fracture intensity, orientation and depth.

- Fiber optics (DAS/DTS and DSS) obtained from two monitoring wells.

- Microseismic event during well stimulation.

This workflow highly relies on acoustic image log analysis which is:

- Highly influenced by human bias (different experts reported significantly different number of fractures, orientations and depths – see figure to right)

- It is extremely time consuming and expensive and prevents deployment in real time (e.g., takes months to interpret)

Automated Machine Learning Workflow developed to:

- Eliminate the human bias in fracture identification using image logs by using high frequency drilling vibration data

- Eliminate the extremely long time required for interpretation of image logs (Using only 10% of interpreted log that enables a near real time application)

- Optimize the machine learning model selection and hyperparameters optimization (Eliminate human bias in model and hyperparameter selection)

Benefits:

- Image log interpretation time and cost dropped by ~10 fold (only 10%-15% of the interpreted image log is required) that enabled the near real time fracture mapping.

- Automated machine learning workflow eliminated the human bias in model and hyperparameters selection.

- High quality fracture network mapping and visualization is achieved using high frequency drilling vibration data.