NETL Researchers Present at DOE’s Cybersecurity and Technology Innovation Conference

NETL experts in energy research-related artificial intelligence/machine learning (AI/ML) and the Energy Data Exchange (EDX®), which curates U.S. Department of Energy (DOE) research data, demonstrated how their work aligns with DOE’s cybersecurity and technology innovation goals at the recently concluded DOE Cybersecurity and Technology Innovation Conference (CyberCon) in Dallas, Texas.

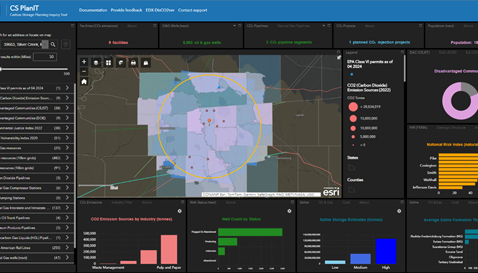

Carbon Storage Planning Inquiry Tool Available on NETL’s Energy Data eXchange

The Carbon Storage Planning Inquiry Tool, or PlanIT, is now available on NETL’s Energy Data eXchange®, providing easy access to explore, query and evaluate thousands of relevant data features and attributes from 14 authoritative sources in one place, to support and accelerate carbon storage feasibility assessments and planning efforts.

NETL Researcher Spreads the Word About Growing Quantum Sensing Expertise

NETL Research Scientist Ruishu Wright is spreading the word about the Laboratory’s growing expertise in quantum sensing — an advanced sensor technology that improves the accuracy of collecting data to assess pipeline integrity and detect gas leakage by sensing changes in motion and electric and magnetic fields on the quantum level — to national audiences.

NETL Online Tool for Data Discovery Supports Development of Permits for Geologic Carbon Storage

The Carbon Storage Planning Inquiry Tool, or PlanIT, is now available on NETL’s Energy Data eXchange®, providing easy access to explore, query and evaluate thousands of relevant data features and attributes from 14 authoritative sources in one place, to support and accelerate carbon storage feasibility assessments and planning efforts.

First-of-Its-Kind Software Integration With Wafer-Scale Engine Achieved

NETL researchers recently took a significant step forward in harnessing the power of the world’s largest computer chip — the Wafer-Scale Engine (WSE) — by using an application programming interface designed in-house to connect commercial computational fluid dynamics (CFD) software through data-file sharing with the next-generation computing technology.

NETL and Cerebras Look to Wafer Scale Engine to Increase Onsite Energy Efficiency

NETL and project partner Cerebras are advancing high-performance computing (HPC) and artificial intelligence (AI)-physics model coupling that can greatly reduce energy consumption and greenhouse gas emissions associated with energy research projects by as much as 30%.

Carbon Management Research Project Review Meeting Set for August in Pittsburgh

Some of the nation’s top scientists and engineers will gather in Pittsburgh, Pennsylvania, beginning Aug. 5 for the 2024 FECM/NETL Carbon Management Research Project Review Meeting to discuss climate change mitigation research and share updates on their efforts to advance innovative solutions for a sustainable energy future.